Whether you are new to laser welding machines or have been using them for many years, the Laser Welding Machine Maintenance Manual will be an indispensable tool for you. This manual provides users with comprehensive maintenance guidance, from basic daily maintenance to complex troubleshooting, so that you will no longer be at a loss when facing equipment problems, but will confidently solve every challenge.

Common equipment failures and causes you should know

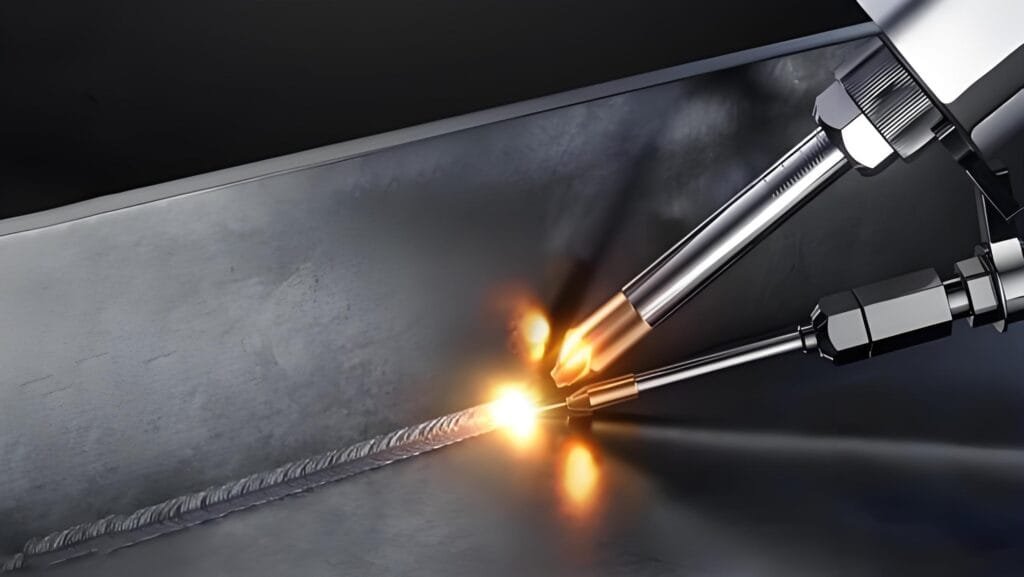

If you frequently use laser welding machines, you may have encountered various equipment problems. For example, have you noticed that the laser output power suddenly drops during welding? In this case, even if you are skilled in operation, the welding effect is difficult to achieve the ideal state. The problem may be that the laser source performance is degraded, the optical path is contaminated, or the cooling system fails to dissipate heat in time.

Another headache is the overheating of the welding head. Especially in high-intensity operations, excessive temperatures will affect the welding stability and may even cause the equipment to stop operating. This is usually because the cooling system is not perfect or the heat dissipation design fails to keep up with the load requirements of the equipment.

And unstable welding results are more hidden problems. At first you may think it is just a small mistake in operation, but in fact, it may be inaccurate alignment of the optical system, uneven airflow control, or even the quality of consumables. All of these failures can seriously affect production efficiency, which is why you need to carefully read and execute every step in the Laser Welding Machine Maintenance Manual.

Step-by-step troubleshooting

The decrease in laser output power will directly affect the welding effect, but it can usually be troubleshooted and solved by the following steps:

Step 1: Check the optical lens.

Turn off the power of the equipment and carefully check all optical lenses in the laser path, especially the focusing lens and the reflector. Observe whether there is dust, oil stains or scratches. If there is contamination, clean the lens with a special optical cleaner and a dust-free cloth. If the lens is damaged, it is recommended to replace it.

Step 2: Check the laser source.

If the problem is not solved after cleaning the lens, observe whether the laser source output is stable. Check the output power through the device control panel. If the output power is lower than the rated value, it may be that the laser is aging or the internal optical path is offset. It is recommended to contact technical support for calibration or replacement of the laser source.

Step 3: Check the cooling system.

Insufficient laser output power may also be related to the cooling system. Check whether the coolant level is within the normal range, whether there is leakage or blockage in the cooling line. If there is a problem, replenish or replace the coolant in time, and clean or dredge the cooling line.

Through the above steps, most power reduction problems can be solved. If it still does not return to normal, it is recommended to refer to the equipment manual for further reference.

Overheating of the welding head may cause poor welding or even equipment shutdown. The following are specific troubleshooting steps:

Step 1: Check the coolant status.

Overheating is usually caused by insufficient cooling. First check whether the coolant level reaches the recommended value. If the level is too low, replenish it in time. In addition, observe the color and clarity of the coolant. If it is turbid or discolored, replace it with a new coolant immediately.

Step 2: Check the cooling line.

If the coolant is normal, then check whether the cooling line is unobstructed. This can be judged by observing the circulation speed of the coolant. If the flow rate slows down significantly, there may be a blockage or air entering the line. After cleaning the line or exhausting the air, restart the equipment to observe whether it improves.

Step 3: Check the cooling fan.

The heat dissipation efficiency of the welding head also depends on the operating condition of the fan. Check whether the fan is running normally, whether there is any abnormal sound or dust accumulation. If the fan fails or there is too much dust accumulation, clean it or replace it in time.

Through these three steps, the temperature of the welding head can be effectively reduced to ensure the normal operation of the equipment.

Unstable welding results are usually manifested as inconsistent weld width and uneven strength. The following steps can help solve it:

Step 1: Check the optical path alignment.

Optical path deviation is a common cause of unstable welding. After turning off the power of the equipment, check whether the laser beam is accurately aligned with the optical axis of the welding head. If deviation is found, use the optical path calibration function of the equipment to readjust and ensure that the beam is centered on the welding point.

Step 2: Check the shielding gas flow.

Unstable shielding gas flow can also affect welding quality. Check the gas flow meter to ensure that the gas supply is stable. If the flow is insufficient or fluctuating, it may be that the gas bottle pressure is insufficient or the pipeline is leaking. The gas bottle needs to be replaced or the pipeline needs to be repaired in time.

Step 3: Check the welding material and fixture.

Uneven materials or loose fixtures may also cause unstable welding results. Make sure the surface of the welding material is flat and uncontaminated, and check whether the fixture is firmly fixed. If there is a problem, adjust or replace the fixture and weld again.

After completing these steps, the welding effect usually returns to normal.

How to prevent laser welding machine failures-starting from details

Preventing laser welding machine failures needs to start with daily details. The following are several easily overlooked but very important preventive measures:

- Clean the inside and outside of the equipment regularly

After the equipment has been running for a long time, dust and oil are easy to accumulate inside and outside. After turning off the power every week, clean the equipment casing and operation panel with a clean cloth and detergent, and check whether there is dust accumulation inside to ensure that the equipment is clean and free of foreign matter. - Check the power supply and wiring

The instability of the power supply system can cause the equipment to suddenly shut down or degrade performance. Check whether the power wiring is loose and whether the wiring port is oxidized or corroded every month. If problems are found, tighten or replace the cable in time to ensure stable power supply. - Update software and firmware regularly

Many equipment failures may be caused by low software or firmware versions. Check whether the control system of the equipment has a new updated version every quarter, and upgrade it in time to optimize equipment performance and fault diagnosis capabilities.

Daily maintenance starting from details can not only effectively prevent failures, but also improve the overall operating efficiency of the equipment.

Rely on maintenance manuals to ensure stable and efficient production

The efficient operation of the laser welding machine is inseparable from scientific maintenance, and the “Laser Welding Machine Maintenance Manual” is your reliable technical guidance. This manual not only contains the technical specifications and operating guidelines of the equipment, but also provides detailed troubleshooting and solutions for common faults to help users quickly respond to various emergencies.

When you encounter problems with unstable welding results, the manual will guide you step by step to check the optical system, laser output and power supply stability to ensure that each link meets operating standards. As for the maintenance of the cooling system, the manual also provides specific operating steps, from checking the coolant level to cleaning the pipelines, to help you effectively extend the service life of the equipment.

In addition, the manual also particularly emphasizes the importance of regular maintenance, recommending users to develop weekly, monthly and quarterly inspection plans to systematically maintain each key component of the equipment. Relying on this manual, you can not only prevent failures, but also significantly improve production efficiency, so that your equipment is always in optimal condition.