In today’s manufacturing industry, laser engraver for metal has become one of the core technologies in production in many industries with its excellent precision, speed and flexibility. Especially in high-tech industries such as electronics, automobiles, aviation and medical, laser engraver for metal provides a perfect solution to meet the needs of personalized customization and mass production. With the rise of intelligent manufacturing, the addition of automation technology and artificial intelligence has made metal laser marking machines easier and more accurate in operation, and greatly improved production efficiency. Now, more and more companies are choosing laser engraver for metal to optimize production processes and improve market competitiveness. This trend has promoted the rapid popularization and application of laser marking technology.

The working principle and development history of laser marking machine

- Laser engraver for metal uses laser beam to accurately mark the metal surface. Its core principle is that the laser is transmitted through optical fiber and focused on the metal surface, forming high temperature, which then ablates the metal surface to produce the required pattern or text. This non-contact processing method has higher precision and flexibility compared with traditional mechanical engraving, stamping or chemical corrosion. Laser marking machine can achieve fine engraving in a very small area and adapt to a variety of metal materials such as stainless steel, aluminum, copper, etc., and the engraving depth and width can be precisely controlled.

- With the advancement of technology, the speed and efficiency of laser engraver for metal have also been greatly improved, reducing manual operations and errors in the production process. Most importantly, laser marking does not involve pollutants or noise that may be generated in traditional methods, so it is considered an environmentally friendly alternative that meets the requirements of modern manufacturing for green and sustainable development.

Choose suitable metal laser marking machine

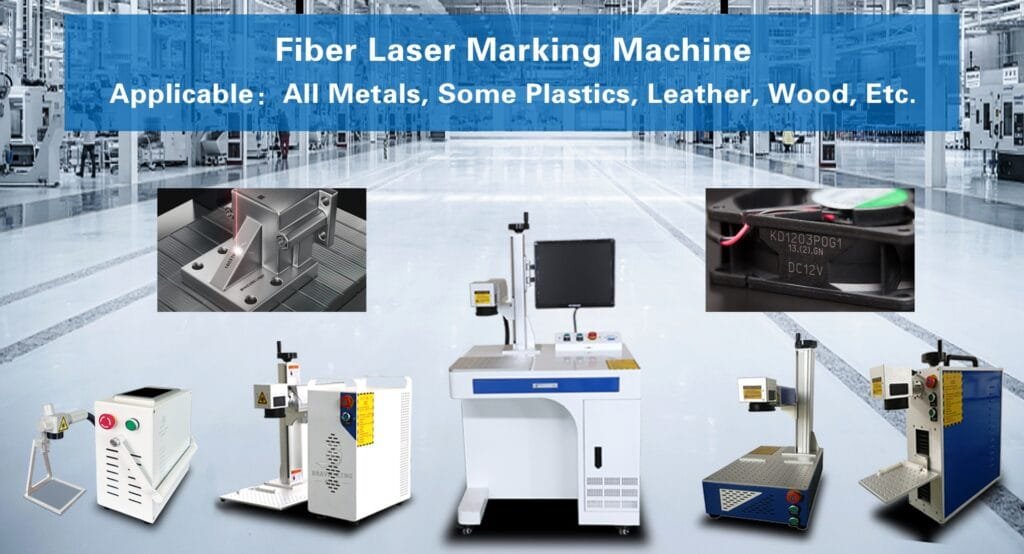

- When buying a laser engraver for metal, buyers need to consider several technical factors, the first of which is the type of laser. Fiber laser is suitable for most metal materials, has high processing efficiency and low energy consumption, and is the most common choice on the market. Power is also a key factor that must be considered when purchasing. Higher power is suitable for processing thicker metals, but it also comes with higher maintenance costs. For the requirements of marking depth, deeper engraving usually requires higher laser power, and speed directly affects production efficiency.

- On this basis, buyers should also think about the balance between long-term investment and short-term needs. If the company has a long-term production plan, choosing an efficient and low-maintenance laser engraver for metal will be a worthwhile investment. Although the initial investment is large, its longer equipment life and lower operating costs will effectively reduce the total cost in the long run.

Choose the most suitable equipment from the user’s perspective

- Judging from user feedback, choosing a suitable laser engraver for metal needs to be evaluated based on specific application scenarios. Jewelers often need equipment that can finely engrave complex patterns and text. Fiber laser marking machines have become the first choice of many jewelers because of their high precision and high-quality output. For small workshops, choosing a convenient handheld laser marking machine can save space and provide flexibility, especially in small batch production.

- For example, a jewelry customization manufacturer successfully engraved customers’ designs on metal rings by using fiber optic laser engraver for metal, which not only improved the personalization of products, but also significantly improved work efficiency. Among large manufacturers, more efficient laser marking equipment not only meets the needs of mass production, but also maintains stability in high-intensity working environments. For example, an auto parts manufacturer used laser marking equipment to improve the clarity of parts marking and improve overall production efficiency.

Daily maintenance to ensure efficient operation of equipment

- In order to ensure that the metal laser marking machine (laser engraver for metal) continues to operate efficiently, daily operation and maintenance are crucial. First of all, correct operating techniques can significantly improve work efficiency. For example, when performing high-intensity marking, reasonably adjusting the laser power and speed can not only extend the service life of the equipment, but also improve the quality of engraving. Regular cleaning of equipment is another important aspect, especially the laser head and lenses. The smoke and metal residue generated during metal marking may affect the laser output, so timely cleaning can avoid unclear marking or reduced efficiency.

- In addition, calibrating the laser position is also a critical operation to ensure accuracy. Before each use, check that the laser’s focus is properly aligned to ensure precise engraving details every time. To avoid common failures, it is recommended to regularly check the cable connections of your device to make sure they are not loose or damaged. If the equipment has poor marking results or abnormal sounds, timely inspection and repair can effectively prevent more serious damage.

How to choose the laser marking machine that best suits your needs

When choosing a suitable laser engraver for metal, the needs of different users determine the direction of choice. For small businesses or entrepreneurs, handheld laser marking machines are usually the best choice because they are small, flexible and affordable. This type of equipment can meet small-batch production and provide a flexible operating experience. For precision jewelers or high-end manufacturers, fiber laser marking machines provide higher engraving accuracy and detail processing capabilities, and are particularly suitable for high-demand crafts engraving. For large-scale production companies, it is crucial to choose an efficient and stable laser marking equipment.

At this time, more attention is paid to the durability, production efficiency and long-term maintenance costs of the equipment. In the selection process, comprehensive consideration of production needs, budget and future business expansion can help you find the most suitable laser engraver for metal and ensure a long-term return on investment.