Laser welding is a process utilized to join metals or thermoplastics by employing a laser beam to create a weld. Due to its concentrated heat source, laser welding can achieve high welding speeds in thin materials, measured in meters per minute. In thicker materials, it is capable of producing narrow and deep welds between square-edged parts.

The operation of laser welding involves two fundamentally distinct modes: conduction-limited welding and keyhole welding. The mode in which the laser beam interacts with the material depends on the power density across the beam striking the workpiece.

Conduction-limited welding occurs when the power density is typically below 10^5 W/cm2. The laser beam is absorbed solely at the material’s surface without penetrating it. Conduction-limited welds often exhibit a high width-to-depth ratio.

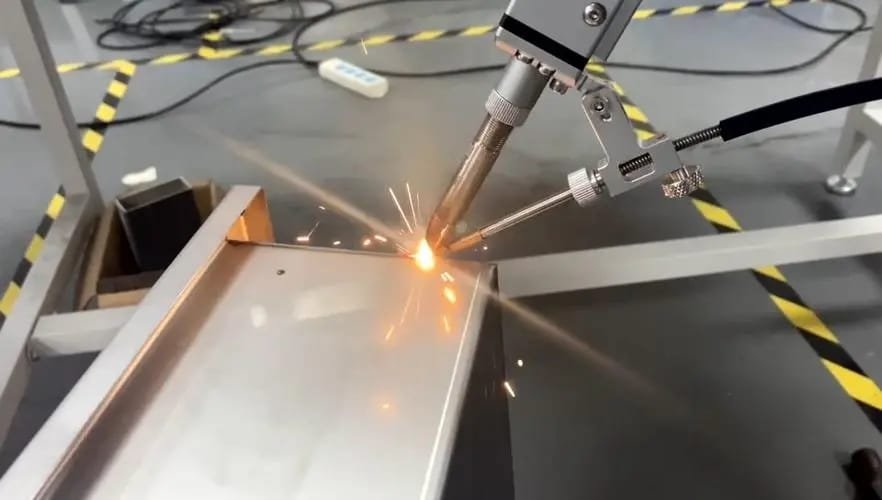

Laser welding is more commonly achieved using higher power densities, employing a keyhole mechanism. When the laser beam is focused to a small spot to produce a power density typically exceeding 10^6-10^7 W/cm2, the material in the beam’s path not only melts but also vaporizes before significant heat removal by conduction. The focused laser beam then penetrates the workpiece, forming a cavity known as a ‘keyhole,’ filled with metal vapor, which in some cases can even be ionized, creating a plasma.

The expanding vapor or plasma helps prevent the collapse of the molten walls of the keyhole into this cavity. Additionally, the coupling of the laser beam into the workpiece is significantly improved by the formation of this keyhole. Deep penetration welding is achieved by traversing the keyhole along the joint to be welded or by moving the joint concerning the laser beam. This results in welds with a high depth-to-width ratio.

Under the influence of surface tension, some of the molten material at the leading edge of the keyhole flows around the keyhole cavity to the back, where it cools and solidifies to form the weld. This leaves the weld cap with a chevron pattern, pointing backward towards the starting point of the weld.