In today’s competitive market, staying ahead means adopting technology that enhances productivity and quality. A laser etching machine does exactly that, solving many challenges associated with traditional engraving methods. These machines provide high-speed, precise engraving on materials ranging from metals to plastics, all while maintaining exceptional detail.

Laser etching machines are particularly beneficial for businesses requiring permanent markings, such as serial numbers or logos. They also cater to the booming demand for personalized products, allowing you to engrave unique designs without compromising efficiency. For industries like aerospace, automotive, or even creative startups, a laser etching machine simplifies production while delivering professional results. Investing in this technology ensures your business stays competitive in a rapidly evolving market.

Laser Etching Simplified: A Step-by-Step Look

The operation of a laser etching machine revolves around converting light energy into heat. When the laser beam focuses on a material, the heat alters the surface, creating permanent and precise marks. This process can involve removing a thin layer of material or changing its color, depending on the desired effect.

Software integrated into the machine ensures precision by guiding the laser beam along the programmed design. The operator can adjust settings such as speed, depth, and intensity to achieve optimal results on different materials. From creating logos on metal to serial numbers on plastic, the process is fast, clean, and requires no additional consumables. This efficiency makes laser etching machines an essential tool for high-quality engraving tasks.

A Deep Dive into Laser Etching Materials and Effects

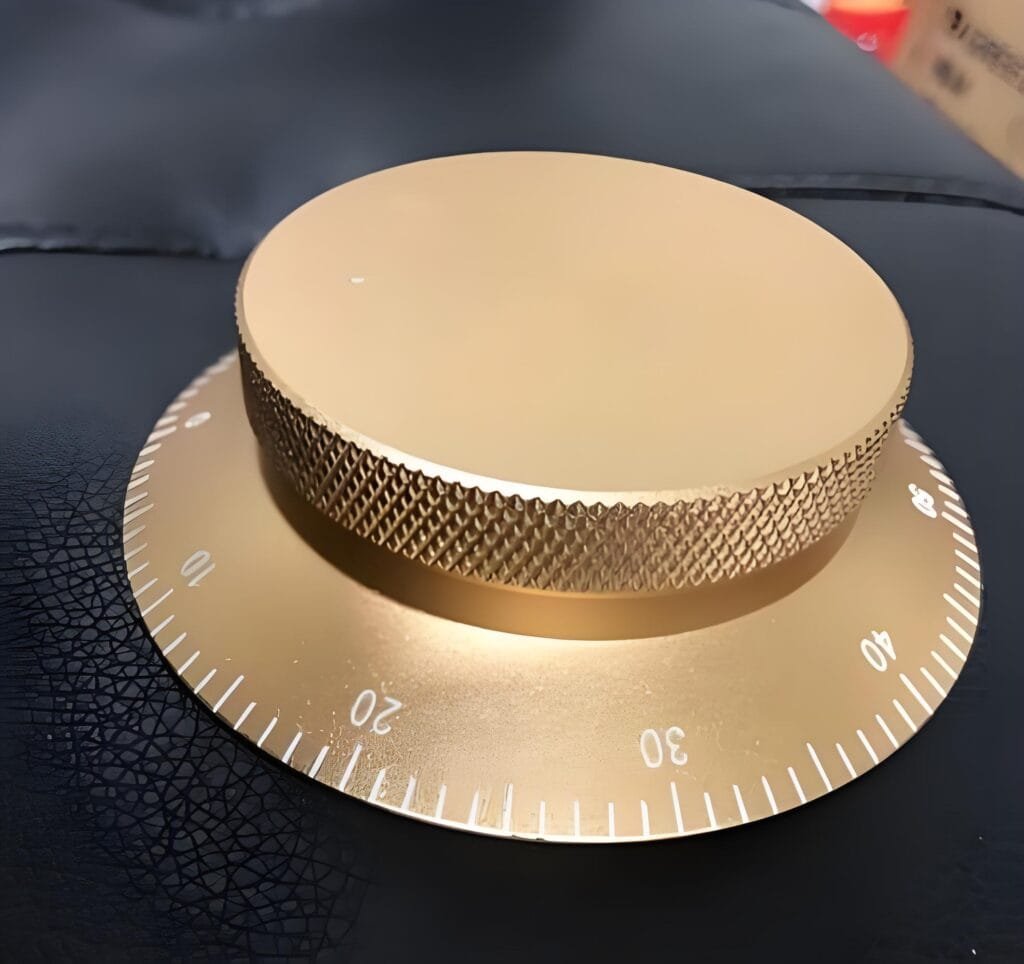

When it comes to materials, a laser etching machine offers unparalleled flexibility. Metals are a top choice, with steel, titanium, and gold delivering clean and durable marks that resist fading or wear. These are perfect for industrial tools, medical instruments, or luxury items.

Plastics, such as ABS, polycarbonate, and acrylic, also perform exceptionally well, producing crisp designs without melting or distortion. On organic materials like wood and leather, laser etching reveals intricate details that enhance their natural appeal. Glass and ceramics require careful calibration but result in elegant frosted effects, often used in gifts or decorative items. Whether you’re crafting a personalized product or creating industrial markings, the adaptability of a laser etching machine ensures exceptional results every time.

Essential Tips for Buying a Laser Etching Machine

When shopping for a laser etching machine, start with your project goals. Are you engraving logos on metals or creating artistic designs on wood? Choose a machine with the appropriate laser type, such as fiber for metals or CO2 for non-metals.

Consider the machine’s ease of use. User-friendly interfaces and intuitive software can make a big difference, especially for beginners. Next, think about energy efficiency and operating costs. Machines with low power consumption reduce long-term expenses. Finally, research the brand’s reputation and user reviews. Reliable brands often offer better support, training resources, and spare parts availability. Investing time in research will help you select a laser etching machine that meets both your creative and operational needs.

Future Trends: The Evolution of Laser Etching Machines

The laser etching machine is poised to become even more integral to manufacturing and design in the years to come. Future developments will focus on improving speed, precision, and ease of use, with the potential for real-time adjustments and feedback during the etching process. In addition, laser etching machines will become more user-friendly, with intuitive touch interfaces and pre-programmed settings for specific materials. This will make them accessible not only to industry experts but also to small business owners and DIY enthusiasts. The adoption of eco-conscious practices, including reduced energy consumption and recyclable materials, will also shape the future of laser etching technology. With these advancements, the future of laser etching will offer greater possibilities for personalization, creativity, and efficiency.