Industrial and government regulations regarding clear and legible product and part identification have contributed to the growing popularity of laser marking, laser etching, and laser engraving services.

Although these three laser processes provide permanent laser marking solutions that fulfill regulations and enhance product distinction, they each have their unique differences.

The key differences between laser marking, laser engraving, and laser etching mainly relate to how each process alters the surface of the material being marked.

Laser marking discolors the surface of the material, while laser etching and engraving remove a portion of the surface area as they mark. The main difference between laser etching and laser engraving lies in the depth to which the laser penetrates the surface.

In this post, we will provide an overview of each process and their respective applications to help you better determine which is most suitable for your specific needs.

Key Differences Between Laser Marking, Etching, and Engraving

Although the terms laser marking, etching, and engraving are often used interchangeably, there are distinct differences between these processes. Each type of process has its own unique applications and attributes that make it more suitable for specific tasks.

The laser marking process is achieved by moving a low-powered beam slowly across the material using a method called discoloration, which creates high-contrast marks without disrupting the material surface. Laser marking is achieved by laser heating the material, causing oxidation under the surface and turning the material black. This process applies low temperatures to metal to anneal the surface, leaving it intact.

Laser marking differs from laser engraving and laser etching in a number of ways. While laser marking discolors the surface, laser engraving removes a portion of the surface area as it marks. Laser etching also removes a portion of the surface area but at a deeper level than laser engraving.

Laser marking is less common and not all places offer these services. It is also referred to as laser coloration or laser dark marking for plastic materials and as charring for metals. There are four common types of laser marking: annealing, carbon migration, foaming and coloration.

Laser marking is popular in the medical device industry for stainless steel and titanium parts but can be performed on other materials as well. It is ideal for bar codes, UID codes, QR codes, logos, and other identification needs.

The differences between laser marking, laser engraving, and laser etching:

Laser engraving is a process that uses a laser beam to physically remove the surface of the material, creating a cavity that reveals an image at eye level. High heat is generated during the laser engraving process, which essentially causes the material to vaporize. This process is quick, as the material is vaporized with each pulse, and creates a noticeable cavity in the surface. To form deeper marks with the laser engraving system, multiple passes are required.

Laser engraving is a subset of laser marking, but there are several differences between them. Laser engraving uses high-powered beams and often requires cooling between pulses to prevent damage to the material. It is typically used for personalized or customized items and is not ideal for marking safety-critical parts. The maximum engraving depth depends on the material, with 0.020″ being the maximum in metals but up to 0.125″ possible in materials such as graphite.

Laser etching, which is a subset of laser engraving, occurs when the heat from the beam causes the surface of the material to change without removing any material. This process can be used on a variety of materials and provides more font and style options than traditional engraving methods. There is a lower chance of product damage or deformation over time compared to traditional engraving practices.

The Laser Etching Process:

Laser etching is a subset of laser engraving that involves using a laser beam to heat the surface of the material without removing any material. This process changes the surface of the material and can be used on a variety of materials. It provides more font and style options than traditional engraving methods and has a lower chance of product damage or deformation over time compared to traditional practices.

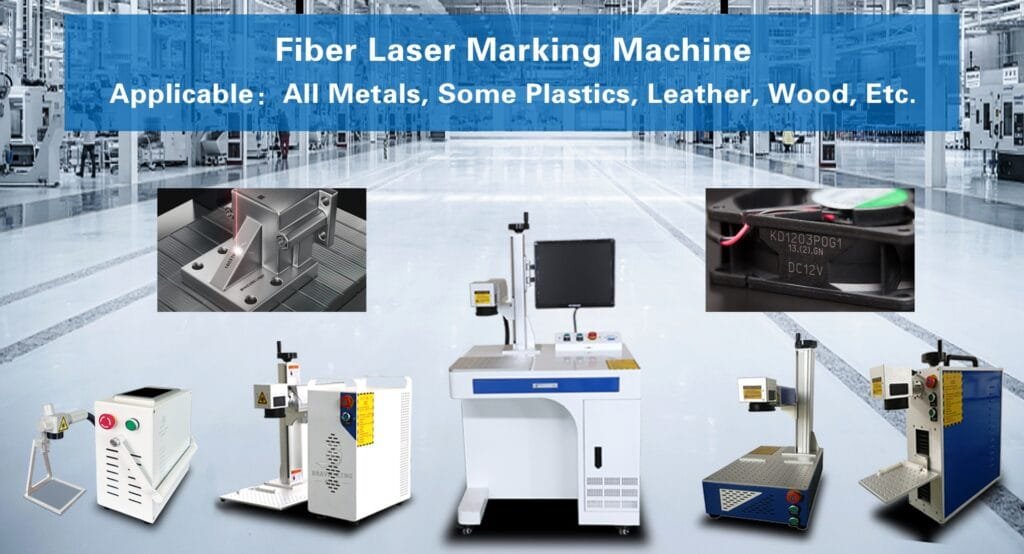

When comparing laser engraving to traditional engraving practices, laser engraving offers advantages such as being able to mark on a variety of materials, including metals, plastics, wood, leather, and glass surfaces. It provides more font and style options and is typically faster than traditional methods. Additionally, there is a smaller chance of product damage or deformation over time with laser engraving compared to traditional engraving practices.