In the realm of modern manufacturing and customization, laser etching machine have become indispensable tools. Known for their precision and versatility, these machines offer unmatched performance in creating permanent marks on a variety of surfaces. From industrial applications to personalized gifts, laser etching machines are revolutionizing the way we mark, identify, and decorate materials.

In this article, we’ll explore the key characteristics of laser etching machine, their functionalities, and the distinct advantages they bring to various industries.

What is a Laser Etching Machine?

A laser etching machine uses a focused beam of light to create markings on a surface by removing or discoloring a thin layer of the material. Unlike traditional engraving, etching typically involves minimal material removal, making it ideal for delicate applications where precision and surface integrity are critical.

How Does Laser Etching Machine Work?

The machine directs a highly concentrated laser beam onto the material’s surface. The heat generated by the laser alters the material’s appearance, either by vaporizing the surface layer or by causing a chemical reaction that changes its color. This results in a permanent, highly detailed mark that is both durable and resistant to wear.

Key Features of Laser Etching Machine

1. High Precision and Detail

Laser etching machines excel in creating intricate designs and fine details. With precision levels measured in microns, these machines can produce sharp, clear marks that are difficult to achieve with traditional methods.

2. Non-Contact Process

Since the laser beam does not physically touch the material, there is minimal risk of surface damage. This feature is particularly advantageous when working with delicate or sensitive materials like glass, ceramics, or thin metals.

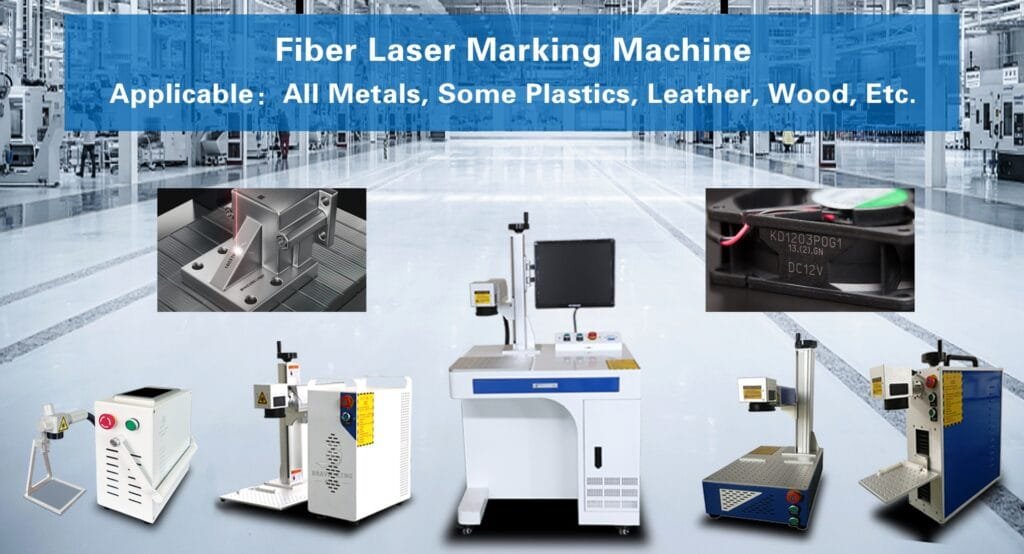

3. Versatility in Materials

Laser etching machines can work on a wide variety of materials, including:

- Metals: Stainless steel, aluminum, brass, copper.

- Plastics: Polycarbonate, ABS, acrylic.

- Organic Materials: Wood, leather.

- Other Surfaces: Glass, ceramics, and even coated surfaces.

4. Software Integration

Modern laser etching machines are equipped with advanced software that allows users to design and edit patterns directly on a computer. The integration of CAD (Computer-Aided Design) or vector files makes it easy to create complex and customized designs.

5. Automated Operations

Many laser etching machines come with automated features such as rotary attachments for cylindrical objects, conveyor systems for mass production, and built-in sensors for quality control. These automation features streamline the etching process and improve productivity.

Core Functions of Laser Etching Machine

1. Marking and Labeling

Laser etching is widely used for marking serial numbers, barcodes, and QR codes on products for identification and traceability. These marks are highly durable and remain legible even under harsh conditions.

2. Decorative Etching

Laser etching machines can create visually appealing designs, patterns, and logos on a range of surfaces. This function is popular in the production of customized gifts, jewelry, and promotional items.

3. Functional Etching

In some applications, etching serves a functional purpose. For instance, it can improve grip by adding texture to a surface or assist in calibration by marking measurement scales.

4. Surface Preparation

In industrial settings, laser etching can be used to prepare surfaces for subsequent processes such as coating or bonding. The laser can create micro-textures that enhance the adhesion of paints or adhesives.

Advantages of Using a Laser Etching Machine

1. Superior Mark Quality

Laser etching produces high-contrast, precise marks that are easy to read and aesthetically pleasing. The non-contact nature ensures that the marks are smooth and free from burrs or rough edges.

2. Durability and Longevity

The marks created by laser etching are resistant to fading, corrosion, and wear, making them suitable for use in harsh environments. This durability is critical for applications in aerospace, automotive, and medical industries.

3. Eco-Friendly Process

Laser etching is a clean and environmentally friendly technology. It doesn’t require the use of inks, chemicals, or other consumables, thereby reducing waste and pollution. Additionally, the process generates minimal noise and dust.

4. Cost Efficiency

While the initial investment in a laser etching machine may be high, its operational costs are relatively low. The absence of consumables, combined with the machine’s high speed and efficiency, leads to significant cost savings over time.

5. Versatility Across Industries

Laser etching machines are used in a wide array of industries, such as:

- Electronics: Marking circuit boards, components, and housings.

- Automotive: Etching VIN numbers, logos, and part identification marks.

- Medical: Marking surgical instruments and medical devices with traceable codes.

- Aerospace: Creating marks that withstand extreme conditions.

- Retail and Consumer Goods: Personalizing items like trophies, plaques, and gadgets.

6. High Throughput

The speed of laser etching allows for rapid production cycles, which is beneficial in industries requiring high-volume output. The automation features further enhance productivity by reducing manual intervention.

7. Customization Capabilities

With laser etching, manufacturers can easily switch between designs or modify them to meet specific customer requirements. This flexibility is crucial in sectors like fashion, interior design, and personalized gifting.

Industries Benefiting from Laser Etching Machine

1. Manufacturing and Industrial Applications

In heavy industries, laser etching ensures permanent marking for parts tracking and quality assurance. It also aids in creating safety and instruction labels that must endure extreme conditions.

2. Medical and Pharmaceutical

The medical industry leverages laser etching for traceable marks on devices, ensuring compliance with strict regulatory standards. The marks remain sterile and durable throughout the product’s lifespan.

3. Jewelry and Luxury Goods

Laser etching adds a personal touch to luxury items. From engraving initials on rings to creating intricate patterns on watches, it enhances the aesthetic value of high-end products.

4. Aerospace and Defense

Aerospace applications demand precision and reliability. Laser etching provides high-contrast, durable marks that can withstand extreme temperatures and mechanical stresses.

5. Retail and E-commerce

Personalized products are a major trend in retail. Laser etching machines enable businesses to offer customized solutions, such as engraved phone cases, water bottles, and notebooks.

Conclusion

A laser etching machine is a powerful tool that combines precision, versatility, and efficiency. Its ability to work on a wide range of materials and produce high-quality, permanent marks makes it invaluable across numerous industries. Whether you’re looking to streamline your manufacturing process, enhance product customization, or ensure regulatory compliance, investing in a laser etching machine can be a game-changer for your business.

By understanding the features, functions, and benefits of laser etching machines, you can unlock new possibilities for innovation and growth in your industry.