In today’s industrial landscape, with the rise of Industry 4.0, Laser Engraving Machines are gradually demonstrating their significant role as an advanced manufacturing technology. In this article, we will explore the key role of Laser Engraving Machines in Industry 4.0 and look into their future prospects in intelligent manufacturing and automated production.

1. Background of Industry 4.0 and Integration of Laser Engraving Machine

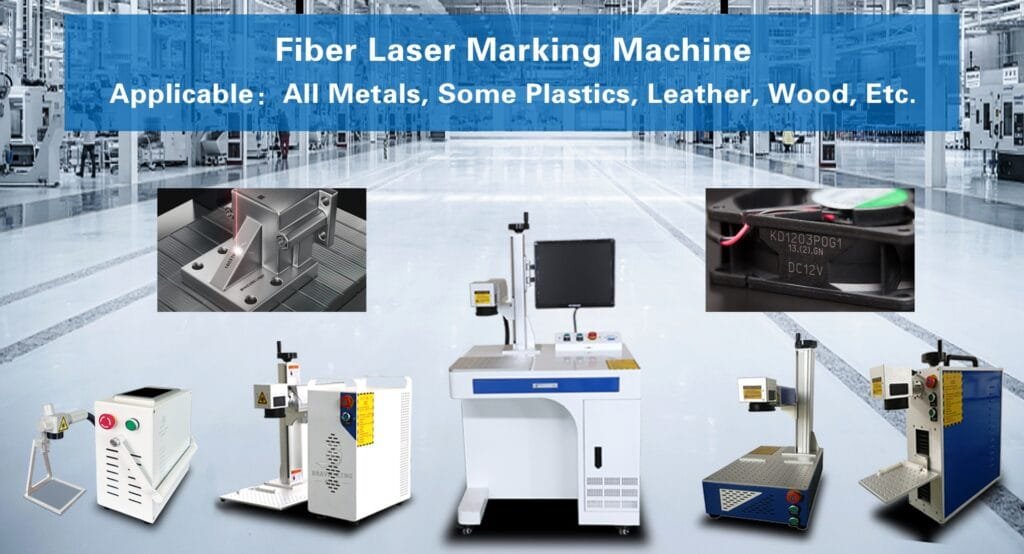

Industry 4.0 refers to the transformation of traditional manufacturing processes into intelligent, efficient, and automated production through the integration of digital technologies and internet connectivity. Laser marking machines have become an integral part of this concept by incorporating digital production. In the era of Industry 4.0, laser marking machines not only achieve high-precision product marking but also seamlessly connect with other intelligent devices, facilitating more efficient production processes.

2. Key Application Areas of Laser Engraving Machine

The application of laser marking machines in the Industry 4.0 era is extensive and diverse. In the automotive manufacturing industry, laser marking machines are used to permanently mark components for traceability and management purposes. In the electronics manufacturing sector, these machines directly mark information such as serial numbers and QR codes on electronic components, enhancing production efficiency and quality control. Additionally, laser marking machines play crucial roles in aerospace, medical devices, and other industries.

3. Advantages of Laser Marking Machine in Intelligent Manufacturing

Laser marking machines possess unique advantages in intelligent manufacturing processes. Firstly, their non-contact marking method avoids damage to the surface of objects, ensuring product quality. Secondly, these machines have high automation capabilities, enabling batch production and increasing production efficiency and capacity. Most importantly, laser marking machines, through digital control, allow for personalized customization, meeting the diverse demands of the market.

4. Future Development Trends of Laser Marking Machine

As Industry 4.0 continues to evolve, laser marking machines will continue to flourish in the future. The laser technology is expected to improve, achieving higher marking precision and speed, while reducing equipment costs, making laser technology more accessible to small and medium-sized enterprises. Moreover, the integration of laser marking machines with artificial intelligence and big data analysis is likely to enable more intelligent manufacturing, further enhancing production efficiency and quality.

Conclusion

Laser marking machines play a crucial role in the Industry 4.0 era, with a wide application range and evident advantages. As technology continues to innovate and advance, laser marking machines will continue to be instrumental in the field of intelligent manufacturing. Enterprises should closely monitor the development trends of laser marking technology and actively adopt relevant equipment to maintain a competitive edge in the fiercely competitive market and achieve more efficient and intelligent production.