The woodworking industry has long been associated with craftsmanship and bespoke creations. However, in today’s digital age, the demand for customization and personalized products is soaring. In this context, laser marking technology emerges as a game-changer, offering precise, versatile, and efficient solutions for customizing wood products. This article delves into the transformative potential of laser marking technology in the woodworking industry, exploring various applications through real-world case studies.

#### Introduction to Laser Marking Technology

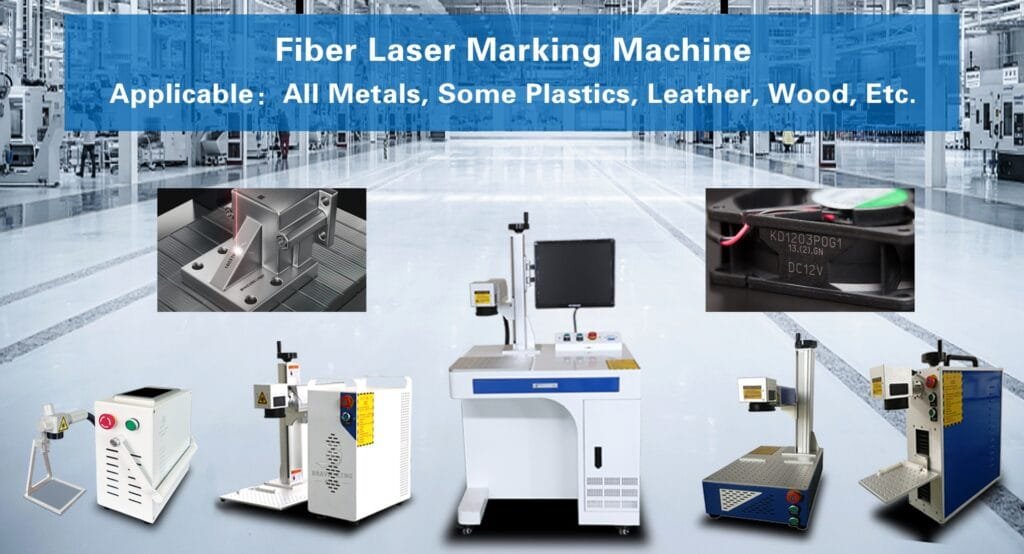

Laser marking technology utilizes high-energy laser beams to create permanent marks on various surfaces. Unlike traditional methods such as engraving or printing, laser marking offers unparalleled precision, speed, and flexibility. It allows for the customization of wood products with intricate designs, logos, serial numbers, or even personalized messages, catering to the growing demand for unique and bespoke items.

#### Case Studies of Laser Marking in the Woodworking Industry

1. **Custom Furniture Branding:** A high-end furniture manufacturer seeks to differentiate its products through unique branding. By employing laser marking technology, the company can precisely etch its logo onto wooden surfaces, ensuring a consistent and aesthetically pleasing branding solution across its product line. This approach not only enhances brand recognition but also adds value to the furniture pieces.

2. **Artisanal Woodcraft Personalization:** An artisanal woodcraft workshop specializes in handcrafted wooden gifts and keepsakes. To meet the demand for personalized products, the workshop adopts laser marking technology to offer custom engraving services. Customers can now request their names, dates, or special messages to be engraved onto wooden items such as photo frames, cutting boards, or jewelry boxes, adding a personal touch to each creation.

3. **Interior Design Customization:** In the realm of interior design, laser marking technology enables unparalleled customization opportunities. From bespoke wooden signage for commercial spaces to intricately patterned wall panels for residential interiors, designers can leverage laser marking to bring their visions to life with precision and efficiency. This level of customization not only enhances the aesthetic appeal of spaces but also reflects the unique identity of the occupants.

4. **Architectural Woodwork Identification:** In the construction industry, laser marking technology plays a crucial role in identifying and labeling wooden components used in architectural projects. By marking each piece with detailed information such as dimensions, material specifications, or installation instructions, contractors can ensure accurate assembly and streamline the construction process. Moreover, laser markings offer long-lasting durability, resisting wear and tear even in harsh environments.

#### Advantages of Laser Marking for Customization in Woodworking

– **Precision and Detail:** Laser marking technology enables the creation of intricate designs and fine details, allowing for precise customization on wooden surfaces.

– **Versatility and Flexibility:** From logos and graphics to text and serial numbers, laser marking can accommodate a wide range of customization options, catering to diverse customer preferences.

– **Efficiency and Cost-Effectiveness:** Laser marking offers fast processing speeds and minimal material wastage, making it a cost-effective solution for customization in large-scale production or small-batch manufacturing.

– **Durability and Longevity:** Laser markings are permanent and resistant to fading, ensuring that customized wood products maintain their quality and appearance over time.

#### The Future Outlook of Laser Marking in Woodworking

As consumer demand for personalized products continues to grow, the role of laser marking technology in the woodworking industry is poised to expand further. Future developments may include advancements in laser technology, such as higher precision, faster processing speeds, and expanded material compatibility. Additionally, integration with digital design software and automation systems could streamline the customization process, enabling more efficient production workflows.

In conclusion, laser marking technology holds immense promise for the future of customization in the woodworking industry. By enabling precise, versatile, and efficient customization solutions, laser marking empowers woodworkers to create unique and personalized products that resonate with their customers’ preferences and aspirations. As technology continues to evolve, the possibilities for customization in woodworking are limited only by imagination.