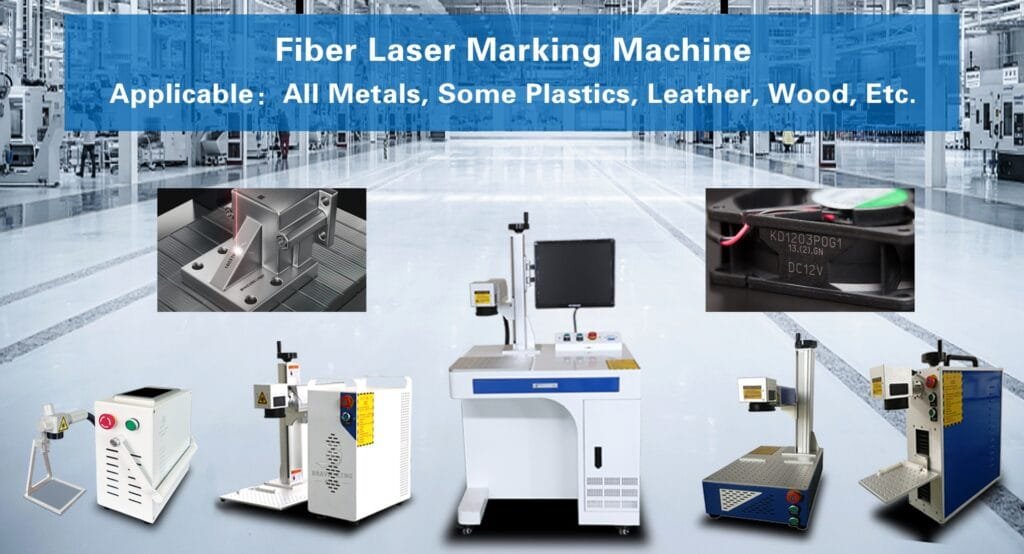

Laser marking machine is a device that uses a laser beam to mark objects’ surfaces, offering advantages such as high precision, speed, and efficiency. In practical applications, laser marking machines find extensive use across various industries, including electronics, automotive, hardware, medical, jewelry, and more. Companies can harness laser marking machines to enhance their work efficiency. Let’s delve into this further.

I. Practical Applications of Laser Marking Machines

Electronics Industry: In the electronics sector, laser marking machines are primarily used for marking and engraving electronic products. For instance, during the production of electronic items like smartphones and computers, laser marking machines swiftly inscribe product models, specifications, and production dates.

Automotive Industry: In the automotive industry, laser marking machines play a key role in marking and identifying auto parts. In the production of automobiles, these machines efficiently engrave part numbers and models, simplifying production and management.

Hardware Industry: Within the hardware industry, laser marking machines are mainly used for marking and engraving metal materials. During the production of hardware products, these machines quickly etch product names and specifications.

Medical Industry: In the medical field, laser marking machines are crucial for marking and identifying medical instruments. In the production of medical devices, these machines rapidly inscribe product names, models, and production dates.

Jewelry Industry: In the jewelry industry, laser marking machines are essential for marking and engraving jewelry items. During jewelry production, these machines swiftly engrave brand logos, serial numbers, and other details.

II. How Companies Can Enhance Work Efficiency Using Laser Marking Machines

Speed Up Marking: Laser marking machines offer rapid marking capabilities, enabling companies to complete a large volume of marking tasks in a short time. This speed boost significantly improves work efficiency.

Reduce Manual Labor: Traditional marking methods often rely on manual labor, consuming time and prone to errors. Laser marking machines provide automation, reducing the need for manual labor and lowering error rates.

Enhance Marking Precision: Laser marking machines offer high precision, capable of creating fine markings on various materials. This enhances product quality and aesthetics, thereby improving efficiency.

Enable Customization: Laser marking machines can achieve personalized customization on a wide range of materials and shapes, meeting individualized consumer demands. Companies can leverage this feature to introduce more personalized products, enhancing competitiveness.

Lower Production Costs: Compared to traditional marking methods, laser marking machines have a longer lifespan and lower maintenance costs, saving companies on production expenses. Additionally, the automation of laser marking reduces manual labor costs.

III. Conclusion

In practical use, laser marking machines find widespread applications in various industries. Companies can utilize these machines to boost work efficiency. By improving marking speed, reducing manual labor, enhancing marking precision, enabling customization, and lowering production costs, businesses can leverage laser marking machines to enhance work efficiency, product quality, and competitiveness.