In the field of industrial manufacturing, precision and efficiency are crucial objectives for enterprises. With the continuous advancement of technology, small Laser Engraving Machines have gained significant prominence in precision manufacturing due to their high accuracy, flexibility, and broad applicability. As product marking requirements continue to rise, various industries rely on small Laser Engraving Machines for accurate, durable, and traceable markings. In this article, we will explore several real-world applications to examine the essential role that small laser marking machines play in precision manufacturing.

1. Technical Advantages of Small Laser Engraving Machines

The core advantage of small laser marking machines lies in their ability to mark highly intricate patterns, characters, barcodes, and QR codes on tiny surfaces. These machines use non-contact laser technology, ensuring no mechanical stress is applied to the marked object, thereby preserving the integrity of the parts. These characteristics make small laser marking machines widely applicable in numerous precision manufacturing scenarios.

- High-precision Marking: Laser Engraving Machines, controlled by computers, can achieve micro-level accuracy, making them ideal for tiny components.

- Wide Applicability: They can handle various materials, including metals, plastics, ceramics, and more, suiting diverse industrial applications.

- Permanent Marking: Laser markings are resistant to wear, ensuring long-term traceability of products.

- Eco-friendly and Efficient: Without the need for consumables, laser marking reduces operational costs and meets environmental standards.

2. Real-world Applications in Different Scenarios

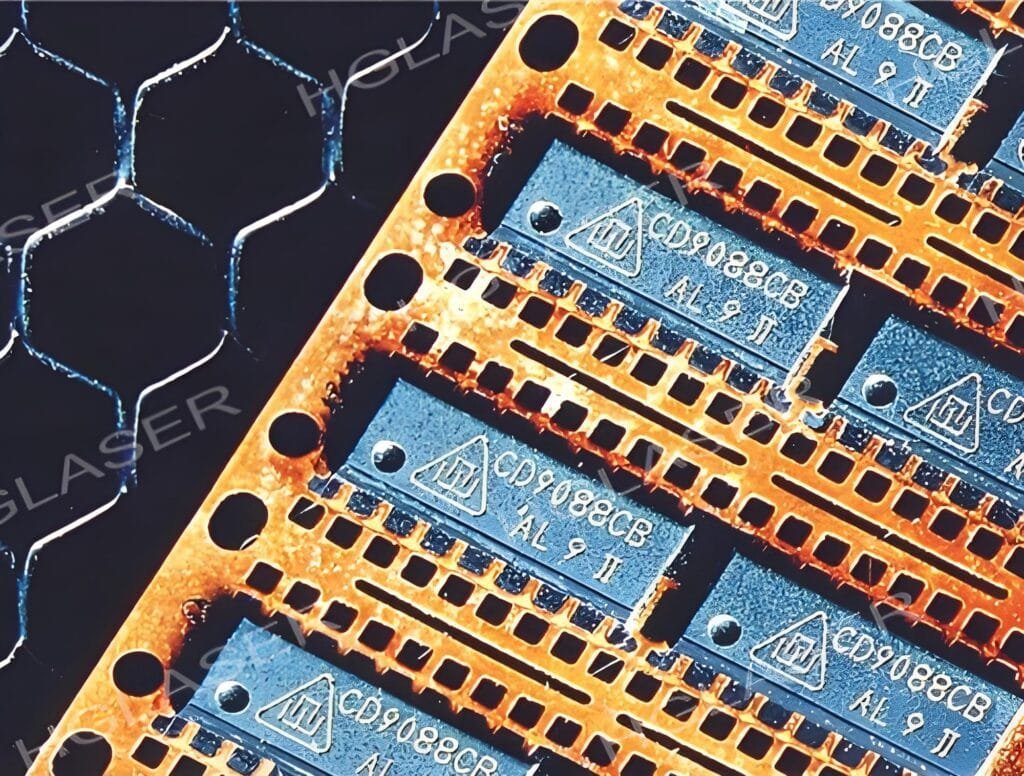

1. Precision Marking in Electronic Components

In the electronics manufacturing industry, small laser marking machines are widely used. Electronic components are often extremely small, but each component needs clear identification, including model numbers, specifications, and production dates. These markings help manufacturers with product tracking and quality management.

Case Study: In the semiconductor industry, chip manufacturers need to mark unique identification codes on each tiny semiconductor wafer to ensure traceability within the supply chain. Traditional marking methods struggle with the fragility and size limitations of wafers, while small laser marking machines can precisely engrave clear QR codes on wafer surfaces without causing damage. This application not only improves production efficiency but also reduces the product defect rate.

2. Traceable Marking in Medical Devices

The medical device industry has strict requirements for product markings, especially for traceability to ensure safety and reliability during use. Laser marking technology, due to its durability and resistance to sterilization and corrosion, has become the preferred marking method in this industry.

Case Study: A medical equipment manufacturer uses small Laser Engraving Machines to engrave labels and serial numbers on surgical instruments, syringes, and implants. The machine can mark on high-hardness materials like stainless steel and titanium, ensuring that markings remain clear even after high-temperature sterilization, meeting rigorous industry standards. This high-precision marking technology significantly enhances quality management in medical device production.

3. Accurate Marking in Automotive Parts

The automotive manufacturing industry involves the production of numerous precision parts, and these parts require clear markings that can withstand extreme operating conditions, such as high temperatures and exposure to chemicals. Small laser marking machines play an essential role in this field.

Case Study: An international automotive parts supplier uses small laser marking machines to code and mark anti-counterfeiting labels on engine components. These markings help manufacturers identify the parts’ origin and trace back to specific production batches in case of quality issues. For critical components like engine blocks and piston rings, laser marking provides permanent and accurate marks that ensure product stability and safety during vehicle operation.

4. Anti-counterfeiting in Luxury Goods and High-end Electronics

Small laser marking machines are also widely used for anti-counterfeiting in luxury goods and high-end electronics. They can generate complex anti-counterfeiting patterns and marks in tiny spaces, making it nearly impossible to replicate through conventional means.

Case Study: A luxury watch brand uses small laser marking machines to engrave unique serial numbers and brand logos on each watch’s dial and back. These fine and intricate anti-counterfeiting marks not only enhance the product’s brand value but also effectively reduce counterfeit products in circulation. The laser marking process allows engraving of detailed patterns within millimeters, adding artistic value without compromising the product’s appearance.

5. Batch Marking in Aerospace Components

In the aerospace manufacturing industry, each part must be marked with batch numbers, serial numbers, and other critical information to ensure traceability throughout its lifecycle. The marking technology required for this field must be highly accurate, durable, and able to withstand extreme environments.

Case Study: An aerospace component manufacturer uses small laser marking machines to mark titanium alloy parts. After undergoing multiple extreme temperature tests, the laser markings remain clear, ensuring traceability and safety during aircraft operations. Additionally, the small laser marking machine’s high efficiency and precision enable the manufacturer to quickly complete batch marking, significantly enhancing production efficiency.

3. Small Laser Marking Machines: Driving the Future of Manufacturing

Small laser marking machines are not only playing a critical role in today’s industrial manufacturing but also paving the way for future advancements. As Industry 4.0 continues to evolve, the demand for smart, digitalized production will only increase, and small laser marking machines, with their flexibility and intelligent control systems, will play an even more vital role in this transition.

In the future, we can expect to see small laser marking machines used in more areas, such as smart home appliances, wearable devices, drone components, and more. Despite their small size, these machines offer enormous benefits in improving production efficiency, enhancing product quality, and ensuring traceability.

Conclusion

Small laser marking machines, with their high precision, broad applicability, durability, and eco-friendliness, are revolutionizing the way precision manufacturing handles product marking. From electronic components and medical devices to automotive parts, luxury goods, and aerospace industries, small laser marking machines have become indispensable tools for precision manufacturing. Through real-world application cases, we can clearly see the powerful capabilities of these machines, fully embodying the concept of “small but mighty.”

Looking ahead, with the continued advancement of technology, small laser marking machines will undoubtedly play an even more significant role in the future of precision manufacturing across various industries.