In today’s automotive manufacturing world, Precision engraving and efficient production are key factors driving innovation. As an advanced industrial application, laser marking technology has become an indispensable part of the automotive industry. This article will take an in-depth look at the use of laser marking machines in the automotive industry and how it is a key element in improving production efficiency.

A new era of precision marking

1. High-Precision engraving

The laser marking machine achieves high-Precision engraving of automobile parts through the high accuracy of the laser beam. This kind of marking is not only visually clear, but also maintains accuracy at a microscopic level, ensuring that products meet strict quality standards.

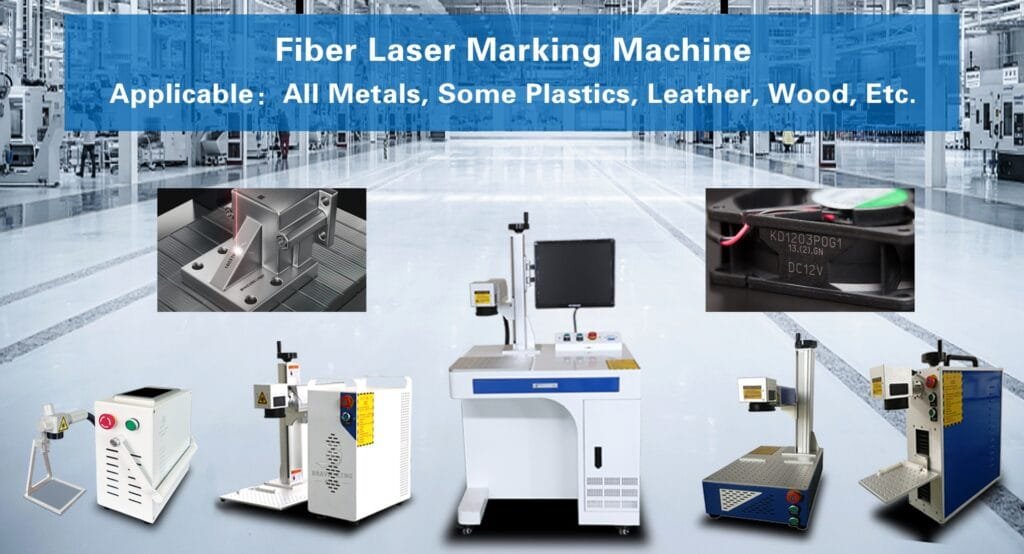

2. Multi-material applicability

Different from traditional marking methods, laser marking technology can be applied to various materials, including metal, plastic and rubber. This provides automakers with greater flexibility to achieve consistent, high-quality marking on different parts.

3. Contactless operation

Laser marking is a non-contact operation method that does not cause physical damage to parts. This is critical to maintaining the integrity and extending the life of components, especially in automotive manufacturing where the appearance of the body is extremely important.

A powerful tool to improve production efficiency

1. Fast and accurate marking process

Compared with traditional marking methods, laser marking machines operate faster and with higher accuracy. This means that more parts can be accurately marked in the same time, thus speeding up the operation of the entire production line.

2. Automation and digitization

Laser marking machines can be integrated with digital manufacturing systems to realize automated marking processes. This integration improves the overall efficiency of the production line, reduces manual intervention, and reduces the probability of human error.

3. Flexible customization capabilities

Automakers often need to mark parts with various information, such as batch numbers, dates and specifications. Laser marking machines can easily achieve customized marking of this information without the need to change molds or adjust production line settings, providing greater flexibility.

Case Sharing: Successful Experience of XYZ Automobile Manufacturing Company

XYZ Automotive Manufacturing Company, a pioneer in automotive innovation, has successfully applied laser marking technology to improve production efficiency. By implementing laser marking on engine parts, they not only improved the clarity of the marks, but also significantly shortened the production cycle. The successful application of this technology makes their products more competitive while reducing production costs.

Future Outlook: The Evolution of Laser Marking Technology

As laser marking technology continues to evolve, we can expect more innovations and improvements. From faster marking speeds to smarter adaptive systems, laser marking technology will continue to play a key role in the automotive industry and drive the entire industry forward.

In general, the precision marking of laser marking machines in the automotive industry not only improves product quality and consistency, but also plays a key role in improving production efficiency. As an important part of modern manufacturing, laser marking technology will surely achieve more significant achievements in the future of the automotive industry.