In the dynamic landscape of digital manufacturing, the integration of cutting-edge technologies is reshaping the industry. Among these innovations, laser marking machines have emerged as trailblazers, particularly in the realm of 3D printing. Let’s delve into the profound impact and frontiers explored by laser marking machines in the 3D printing domain.

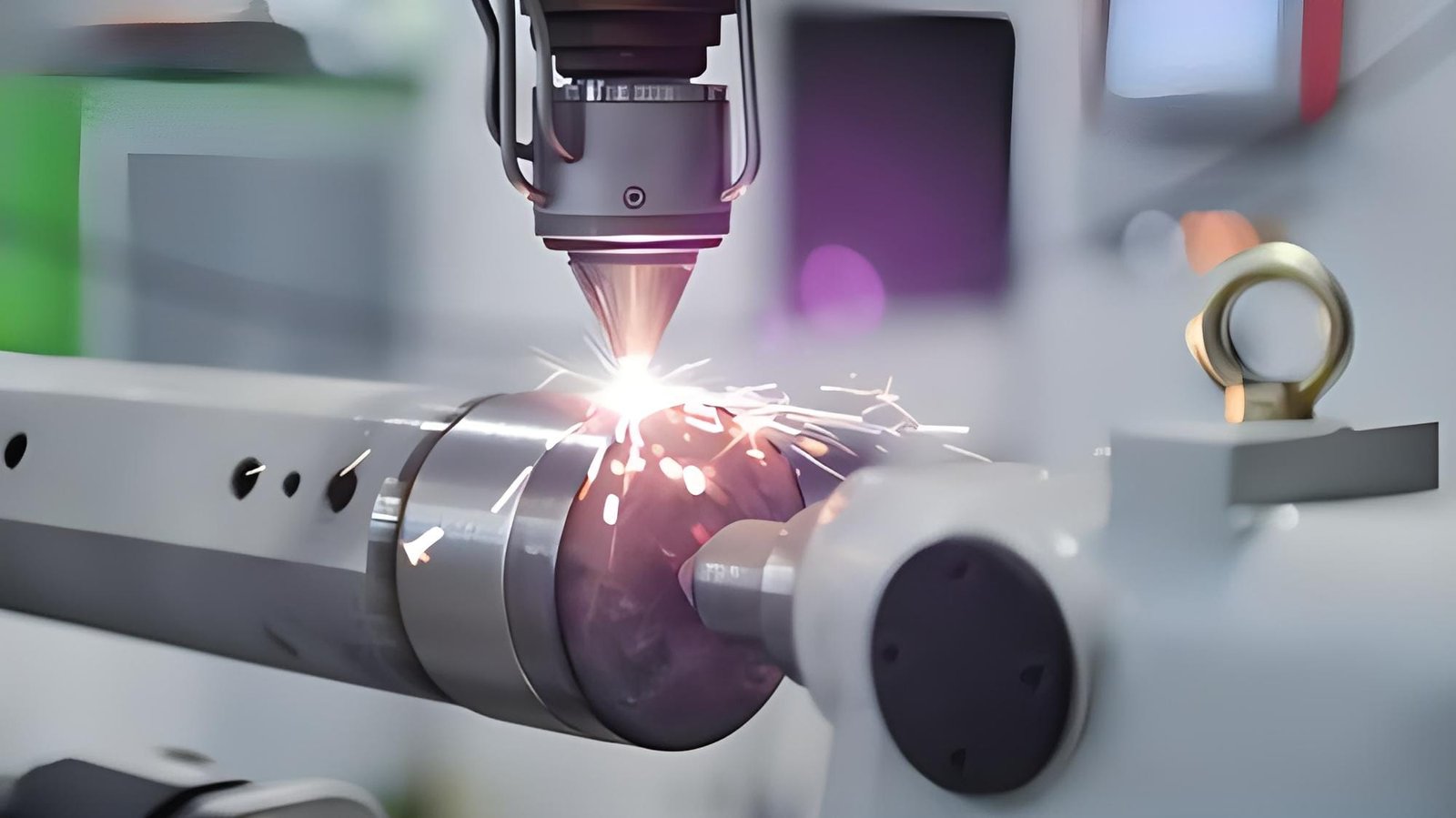

1. Laser Marking Precision Enhancement in 3D Printing

Laser marking technology plays a pivotal role in enhancing the precision of 3D printing processes. By precisely marking reference points and identifiers on 3D-printed objects, laser marking ensures accuracy during post-processing and assembly. This level of precision is crucial, especially in industries requiring intricate and complex components.

2. Unique Identification and Traceability

In digital manufacturing, traceability and identification are paramount. Laser marking machines provide a solution by creating unique and machine-readable identifiers on 3D-printed products. These identifiers enable efficient tracking throughout the manufacturing and supply chain, ensuring quality control and compliance with industry standards.

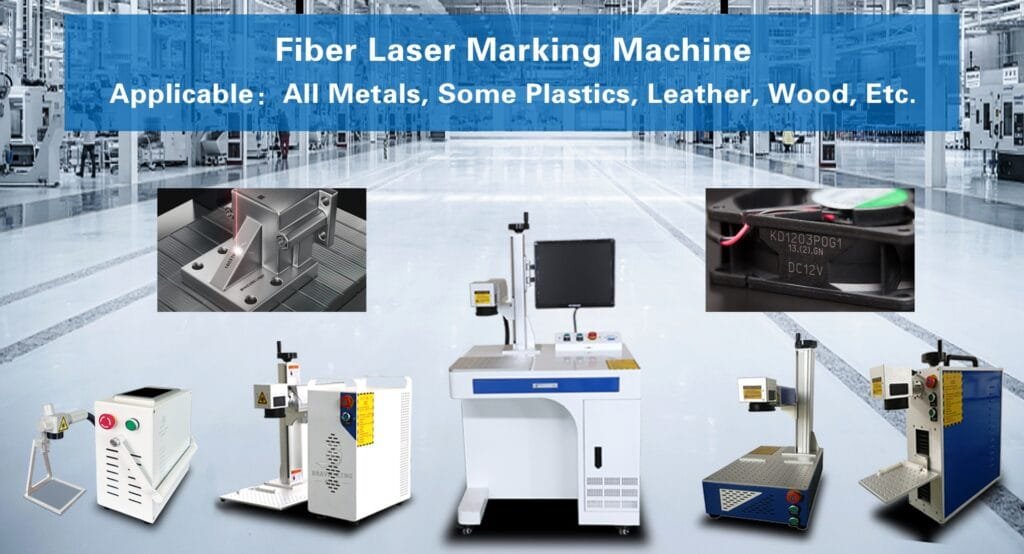

3. Material Diversity: A Canvas for Laser Engraving

The versatility of laser marking machines extends to various materials used in 3D printing. Whether it’s plastics, metals, ceramics, or composites, laser marking allows for intricate and permanent marking on diverse surfaces. This adaptability significantly broadens the scope of applications for 3D printing across industries.

4. Personalization in the Digital Realm

As 3D printing increasingly becomes a tool for personalized manufacturing, laser marking technology steps in to add the finishing touch. Whether engraving logos, names, or intricate designs, laser marking provides a level of personalization that transforms 3D-printed objects into bespoke creations, appealing to a wide range of consumer preferences.

Case Studies: Laser Marking’s Influence in 3D Printing

- Aerospace Industry Innovations In the aerospace sector, laser marking machines are utilized to mark identification codes and part numbers on 3D-printed components. This ensures easy traceability, maintenance, and compliance with stringent industry regulations.

- Medical Prosthetics Laser engraving plays a crucial role in the production of personalized 3D-printed medical prosthetics. Each prosthetic is marked with patient-specific information, allowing for seamless tracking and customization.

Future Prospects: Expanding Horizons in Digital Manufacturing

The journey of laser marking machines in the 3D printing domain is far from over. As both technologies continue to evolve, we can anticipate further exploration into new materials, enhanced precision, and even greater integration with emerging digital manufacturing technologies.

Conclusion

Laser marking machines have proven themselves as leaders in the digital manufacturing landscape, particularly in the 3D printing realm. Their contributions to precision, identification, and material versatility mark a significant step forward in the evolution of digital manufacturing processes. As we stand on the cusp of further innovations, the collaboration between laser marking and 3D printing promises an exciting future for the manufacturing industry.