With the widespread application of plastic products across various industries, the demand for advanced plastic processing techniques continues to rise. Laser marking technology emerges as a versatile and efficient solution in the realm of plastic processing, offering precise and multifunctional capabilities. This article delves into the diverse applications of laser marking in the plastic processing industry, showcasing real-world case studies to demonstrate its effectiveness in different scenarios.

#### Introduction to Laser Marking Technology

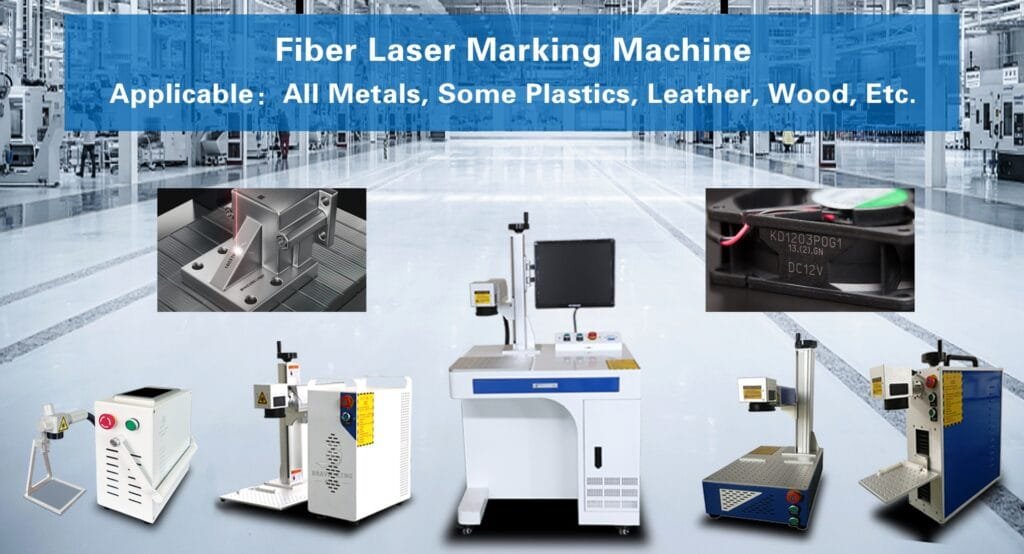

Laser marking technology utilizes high-energy laser beams to create permanent marks on various surfaces. Unlike traditional methods such as engraving or printing, laser marking offers unparalleled precision, speed, and versatility. It enables high-quality marking on plastic surfaces with intricate designs, logos, serial numbers, or personalized information, meeting the growing demand for unique and customized products.

#### Case Studies

1. **Identification on Electronic Product Casings:** A manufacturer of electronic products utilizes laser marking technology to imprint product model numbers, brand logos, and production dates on plastic casings. The high precision and speed of laser marking ensure clear and durable identification, enhancing product quality and credibility.

2. **Marking on Medical Device Components:** Medical device manufacturers employ laser marking technology to label product model numbers, batch numbers, and usage instructions on plastic surfaces. The non-contact nature and high precision of laser marking guarantee clear and accurate identification, complying with the stringent standards of the medical industry.

3. **Labeling Automotive Parts:** Automobile manufacturers mark part numbers, production dates, and quality control information on plastic automotive components using laser marking technology. Laser marking achieves high-precision marking on complex surfaces, ensuring clear and durable identification, thus enhancing part traceability and quality assurance.

4. **Packaging Labeling in the Food Industry:** Food packaging companies utilize laser marking technology to print production dates, shelf-life information, and barcodes on plastic packaging. The high-speed and reliability of laser marking ensure accurate and long-lasting labeling, improving food safety and traceability.

#### Advantages of Laser Marking Technology

– **High Precision and Speed:** Laser marking technology enables high-precision marking of intricate designs and fine details at fast processing speeds, enhancing production efficiency.

– **Non-contact and Non-polluting:** Laser marking process is entirely non-contact, preserving the integrity of plastic surfaces and ensuring cleanliness in the production environment.

– **Durability and Longevity:** Laser markings are permanent and resistant to fading or wear, maintaining clarity and readability over time.

– **Versatility and Flexibility:** Laser marking technology accommodates various marking forms, including text, graphics, and barcodes, catering to diverse application needs.

#### Future Outlook

As laser technology continues to advance and become more accessible, the prospects for laser marking in the plastic processing industry are promising. Future developments may include further improvements in precision and speed, expansion of material compatibility, and realization of more complex and diverse marking requirements. Additionally, with increasing emphasis on environmental protection and sustainability, laser marking technology is expected to evolve towards greener practices, reducing energy consumption and waste generation, thus fostering a more sustainable path for the plastic processing industry.

In conclusion, laser marking technology offers efficient, precise, and reliable solutions for various applications in the plastic processing industry. Through real-world case studies, we witness its significant potential and market value in industries such as electronics, healthcare, automotive, and food. With continuous technological innovation, laser marking is poised to play an increasingly vital role in driving innovation and growth in the plastic processing industry, injecting new vitality and momentum into its development.