In the process of global industrialization, the development of rust removal technology directly affects the production efficiency and environmental friendliness of many industries, especially in automobile manufacturing, aerospace, shipbuilding and heavy industry, where corrosion on metal surfaces often increases repair and maintenance costs. Traditional rust removal methods, such as sandblasting, chemical cleaning and mechanical rust removal, usually require a lot of labor and cleanup work, and can produce hazardous waste and increase environmental burden. Laser rust removal technology has become an ideal alternative due to its precise laser beam control and chemical-free advantages. It can remove rust with less energy consumption and shorter time without causing pollution to the surrounding environment. Therefore, laser rust removal can not only improve production efficiency, but also help major industrial fields achieve significant economic benefits in terms of energy conservation, emission reduction, and reduction of operating costs, making it the first choice for major enterprises when choosing rust removal methods.

Practice and limitations of traditional rust removal methods

- Traditional rust removal methods such as sandblasting, chemical cleaning and mechanical grinding, although widely used in the past, also bring many challenges. In the automotive manufacturing industry, some production lines rely on sandblasting to remove rust from body parts. Although this method can effectively remove the surface rust layer, it is complicated to operate and requires a lot of manual participation. The particles generated during sandblasting pollute the environment, and while removing rust, the metal surface is easily damaged, affecting the subsequent process. Chemical cleaning relies on strong acids or chemical solvents, which not only increases the complexity of the operation, but also may pose a risk to the health of workers.

- The waste liquid generated after cleaning requires special treatment, which increases the environmental burden. In addition, although mechanical grinding can quickly remove rust, it may cause excessive wear to parts with high precision requirements, affecting the performance of the metal. In contrast, laser rust removal technology, with its high efficiency and precision, avoids the environmental pollution and operational complexity caused by these traditional methods without damaging the metal surface, and is a more environmentally friendly and efficient choice.

Environmentally friendly rust removal in manufacturing

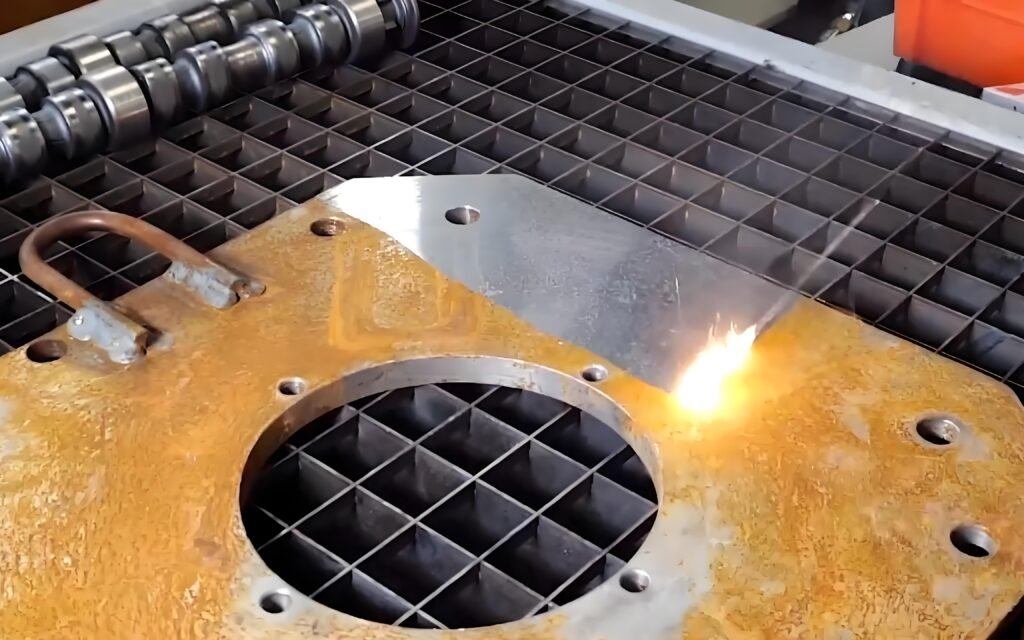

- In heavy industry and manufacturing, the rust problem of metal parts has long plagued production lines, especially those mechanical parts that need to be processed frequently. A machinery manufacturing company decided to use laser rust removal technology to solve this problem. The company introduced efficient laser rust removal equipment, which can not only quickly remove the rust layer, but also finely process the parts without damaging the metal substrate. The biggest advantage of laser rust removal technology is its environmental friendliness. The rust removal process does not require the use of chemical solvents or other harmful substances, thus avoiding the environmental pollution problems caused by traditional rust removal methods.

- The operation of laser machine is extremely simple, and it reduces the complex cleaning work required by traditional methods, which improves production efficiency and product quality as a whole. According to corporate reports, after adopting laser removal technology, the production cycle of parts has been shortened by 30%, maintenance costs have been greatly reduced, and environmental protection effects have also been greatly improved.

Comparison of rust removal technologies in heavy industry: Improvement of efficiency, environmental protection and precision

- In heavy industry, many large equipment and machinery face rust problems. Traditional rust removal methods usually rely on sandblasting or chemical solvents. Although these methods can quickly remove rust, they have certain risks of environmental pollution and equipment damage. For example, in a large machinery manufacturing plant, when using traditional sandblasting, manual operation is usually required, and the particulate matter generated during the sandblasting process seriously affects the cleanliness of the factory environment.

- In contrast, laser rust removal technology can remove the rust layer without contacting the metal surface through a high-precision laser beam, avoiding damage to the substrate. In addition, laser rust removal not only reduces waste emissions, but also improves rust removal efficiency. According to statistics, the application of laser rust removal has reduced the equipment cleaning cycle by 35%, increased production efficiency by 40%, and has almost zero impact on the environment.

From short-term savings to long-term sustainability: the transformational role of laser rust removal

The application of laser rust removal technology in industry is not only a short-term efficiency improvement tool, but also an indispensable innovative technology for enterprises in the pursuit of long-term sustainable development. In the short term, laser rust removal can greatly shorten the rust removal time and improve production efficiency due to its high efficiency and ease of operation; in the long term, laser rust removal technology reduces waste emissions and energy consumption, meets environmental protection requirements, and lays the foundation for the sustainable development of enterprises. More and more companies realize that although the initial investment of laser rust removal is high, it can bring higher returns on investment in the long run by reducing the use of chemicals and waste treatment. Therefore, laser rust removal technology will gradually replace traditional methods in the next few years and become the mainstream solution in the industrial field.