Laser engravers have become indispensable tools for engraving on a wide variety of materials. Among these, metal stands out as one of the most challenging and rewarding surfaces to work with. Whether for marking, etching, or engraving, laser technology provides exceptional precision, speed, and durability in metalworking applications. In this article, we will explore how laser engravers for metal are used across different industries, the key benefits they offer, and the versatility of this technology in modern manufacturing.

Understanding Laser Engraver for Metal

Laser engraving is a process that uses a high-powered laser beam to etch or engrave designs, text, logos, and images onto a material’s surface. Unlike traditional engraving methods, such as mechanical or chemical engraving, laser engraving does not involve physical contact with the material. Instead, the laser uses focused heat to vaporize or melt the surface of the metal, creating permanent marks with exceptional detail.

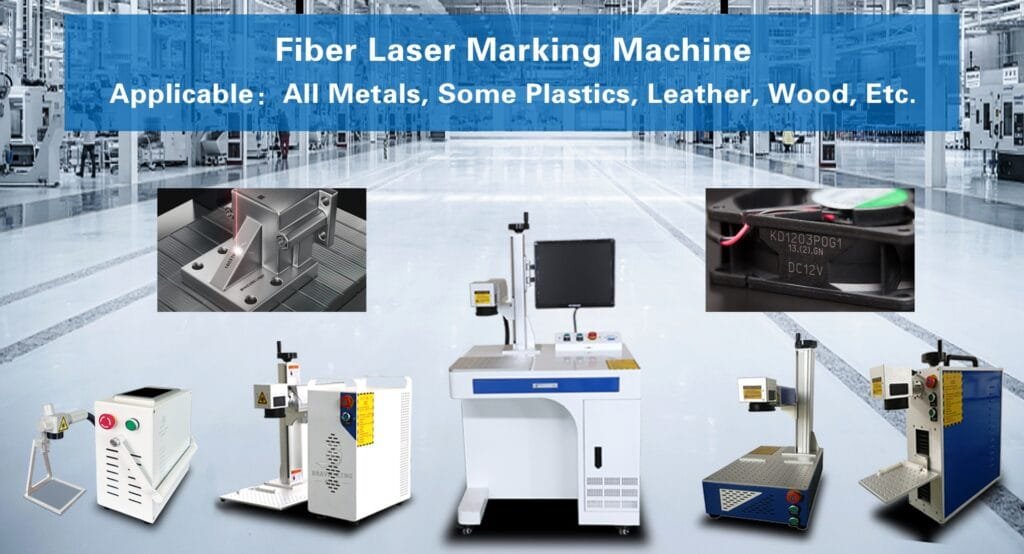

Laser engraving machines for metal are equipped with specialized laser sources such as CO2 lasers or fiber lasers. Fiber lasers, in particular, are highly effective for metal engraving due to their high energy density and precision. These lasers are capable of engraving on a wide range of metals, including stainless steel, aluminum, brass, copper, and titanium, making them incredibly versatile.

Key Advantages of Laser Engraver for Metal

Before diving into specific applications, it’s important to understand the core benefits of using laser engravers for metal:

- Precision and Detail: Laser engravers can achieve extremely fine and detailed results, making them ideal for intricate designs, text, and logos on metal surfaces. Whether it’s a small engraving on a piece of jewelry or a detailed industrial part, the precision of a laser engraver ensures high-quality, consistent results.

- Non-contact Process: Since laser engraving does not physically touch the metal, there is minimal wear on the machine and no risk of damaging the workpiece. This non-contact nature allows for the engraving of delicate or thin metals without causing distortion or deformation.

- Speed and Efficiency: Laser engraving is much faster compared to traditional methods like mechanical engraving. This speed is especially beneficial in industries that require large volumes of parts to be marked or engraved in a short amount of time.

- Minimal Material Stress: Laser engraving produces minimal heat-affected zones, meaning there is less risk of warping or damaging the metal. This makes it an ideal choice for high-value, precision metal parts.

- Versatility: Laser engravers can mark a wide range of metals, including hard and soft metals, alloys, and coated surfaces. The same machine can be used for a variety of applications, increasing operational efficiency.

Applications of Laser Engraver for Metal

Laser engraving for metal has a broad range of applications across various industries. From manufacturing to design, this technology offers solutions that enhance productivity, accuracy, and aesthetics. Let’s take a look at some of the key industries where laser engraving machines are making a significant impact.

1. Manufacturing Industry

In the manufacturing sector, laser engravers are often used for marking parts and components with serial numbers, barcodes, logos, and other identifiers. This is particularly important for traceability and quality control. By engraving vital information directly onto metal surfaces, manufacturers can ensure that parts are properly tracked through the production process and beyond.

- Application Example: In the automotive industry, manufacturers use laser engraving to mark engine components, vehicle identification numbers (VIN), and parts with safety-critical information. This enables efficient tracking and ensures compliance with industry standards.

- Application Example: In aerospace, where precision is critical, laser engraving is used to mark metal components like turbine blades, engine parts, and structural elements with specific codes and maintenance instructions.

2. Jewelry and Fashion Industry

Laser engravers are also widely used in the jewelry and fashion industry to create detailed patterns, engrave names, dates, and logos on rings, bracelets, necklaces, and other metal accessories. Laser engraving allows for intricate designs and customizations that are difficult or impossible to achieve with traditional engraving techniques.

- Application Example: Wedding bands, engagement rings, and other fine jewelry can be personalized with meaningful messages or designs, thanks to the precision of laser engraving.

- Application Example: Designers use laser engraving on metal jewelry to etch intricate patterns, textures, and branding logos, which adds a personal touch to each piece and enhances its uniqueness.

3. Medical Device Manufacturing

The medical device industry relies on precision and reliability. Laser engraving offers a non-invasive method for marking surgical instruments, implants, and medical devices with important information, such as serial numbers, patient data, and regulatory markings.

- Application Example: Stainless steel surgical tools and implants are marked with batch numbers, sterilization dates, and other essential information that can help ensure patient safety and compliance with health regulations.

- Application Example: Medical devices like pacemakers and stents are engraved with identification codes, making them easier to trace in case of recalls or maintenance.

4. Tooling and Machinery

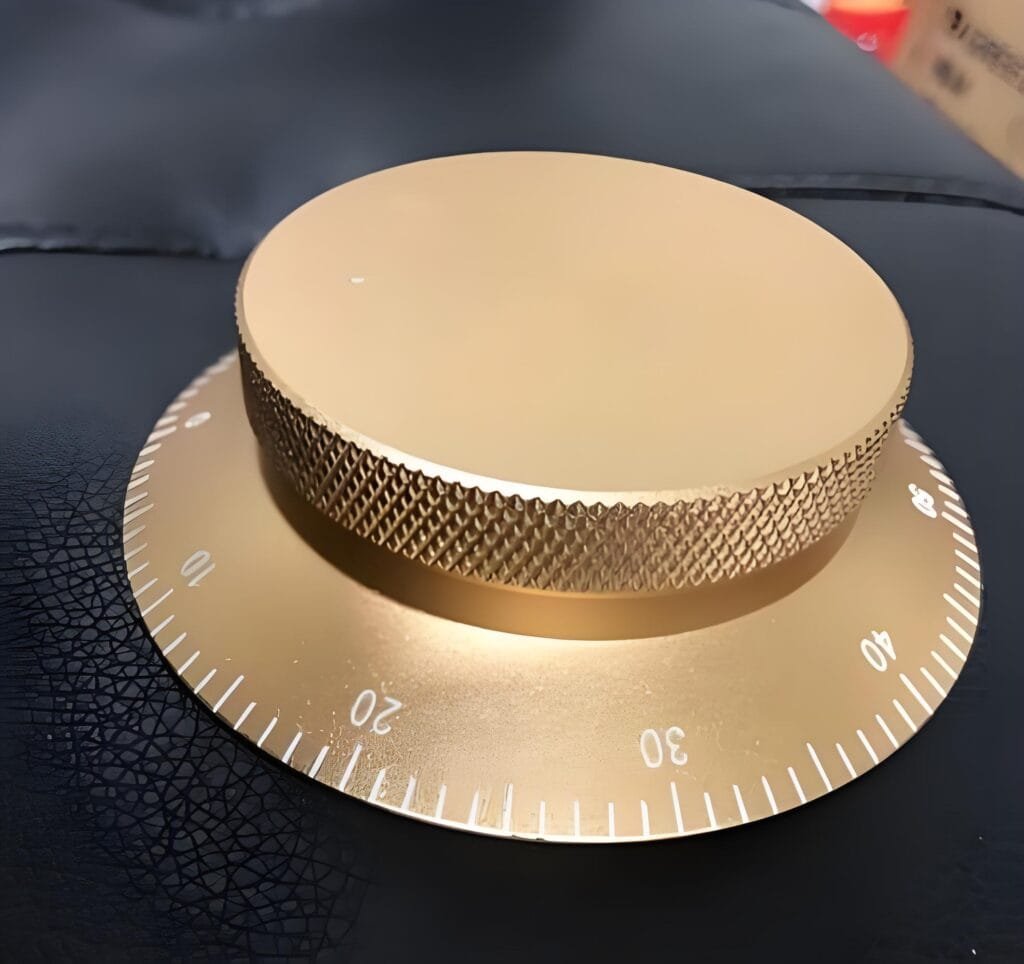

The tooling and machinery industries use laser engravers to mark tools, dies, and molds. Marking these tools with specific information, such as model numbers, part numbers, and calibration details, is essential for maintaining quality standards and optimizing production processes.

- Application Example: Dies and molds used in metal stamping and injection molding are laser-engraved with precise identification and maintenance data to improve operational efficiency and reduce errors.

- Application Example: Laser engraving is used to mark cutting tools with specific part numbers and wear indicators, ensuring that tools are properly maintained and replaced when necessary.

5. Personalized Gifts and Customization

Laser engravers for metal are also gaining popularity in the personalized gift industry, where customization is key. Metals such as stainless steel, aluminum, and even gold are engraved with custom messages, designs, and logos for gifts such as keychains, pens, flasks, and awards.

- Application Example: Customized corporate gifts, such as engraved metal pens or award trophies, are increasingly popular for branding and recognition purposes.

- Application Example: Personalized gifts like metal picture frames, plaques, and keychains are often engraved with names, dates, and meaningful messages for special occasions like weddings, anniversaries, and birthdays.

6. Electronics and Electrical Industry

Laser engraving is also used in the electronics and electrical industry to mark metal components like circuit boards, connectors, and housings. It is crucial for marking these components with identification codes, safety certifications, and other necessary data that can be used for inventory management, repairs, and regulatory compliance.

- Application Example: Electrical enclosures and metal casings for electronic devices are engraved with model numbers, part numbers, and certification logos to facilitate maintenance and ensure regulatory compliance.

- Application Example: Circuit board components are laser-engraved to indicate orientation, batch numbers, and manufacturing details to streamline assembly and quality control processes.

Conclusion: The Future of Laser Engraver for Metal

Laser engraving technology continues to evolve, bringing new possibilities for metal marking and engraving across various industries. The ability to work with different metals, engrave with extreme precision, and deliver high-speed results makes laser engravers an invaluable tool in manufacturing, design, and personalization.

As industries continue to demand greater precision and efficiency, laser engraving on metal will likely play an even more significant role. Its versatility ensures that laser engravers will remain essential across sectors like manufacturing, jewelry, medical devices, and consumer products, while its applications will continue to grow and expand with advances in technology.

In summary, Laser Engraver for Metal has proven to be a transformative solution, enhancing product quality, customization, and traceability while reducing operational costs and time. Whether in the factory, on the design desk, or in the hands of artisans, laser engravers for metal are set to remain at the cutting edge of industrial innovation.