In the realm of modern technology, the demand for smaller, more efficient electronic devices continues to surge. This necessitates manufacturing processes capable of delivering precision at a microscopic level. Among these processes, laser welding machines have emerged as indispensable tools, enabling the creation of intricate microelectronic devices with unprecedented accuracy and reliability.

Precision at the Microscopic Level

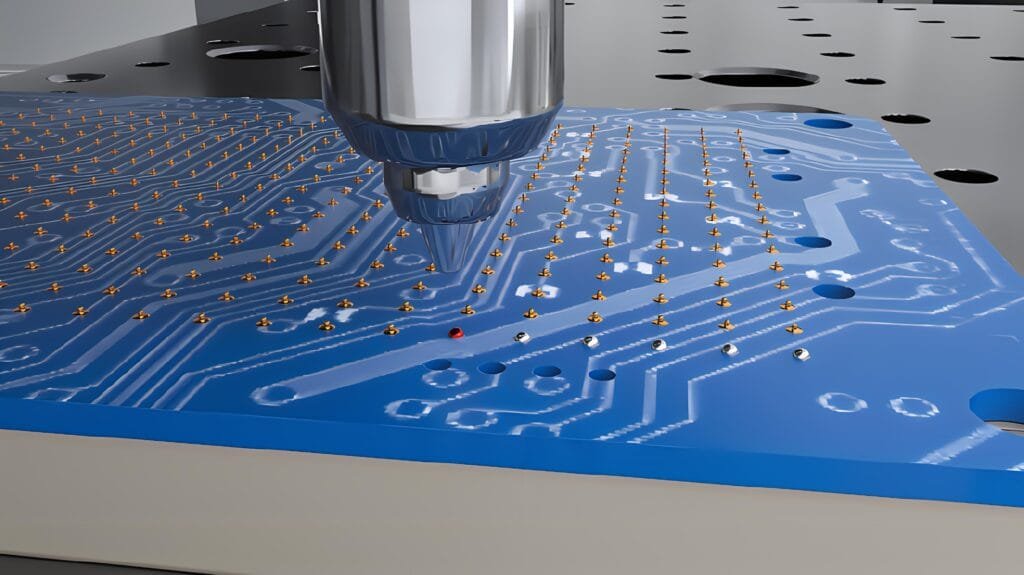

Microelectronic devices, such as microchips, sensors, and medical implants, require components to be assembled with utmost precision. Traditional welding methods often fall short in meeting the stringent requirements of these devices due to their inability to deliver precision at such small scales. Enter laser welding machines – equipped with highly focused laser beams, they offer unparalleled precision and control, allowing for the assembly of intricate components with microscopic accuracy.

Miniaturization without Compromise

The miniaturization trend in electronics demands that devices become smaller while maintaining or even enhancing their functionality. Laser welding machines play a pivotal role in this endeavor by enabling the fabrication of miniature components with uncompromised quality. By precisely fusing tiny parts together, these machines facilitate the creation of compact yet powerful electronic devices that push the boundaries of what is technologically achievable.

Ensuring Reliability and Durability

Microelectronic devices often operate in harsh environments and are subjected to various stresses during their lifespan. As such, ensuring the reliability and durability of these devices is paramount. Laser welding, with its ability to create strong and consistent bonds between materials, provides an ideal solution. The welded joints exhibit high strength and integrity, capable of withstanding extreme conditions without compromising performance, thus enhancing the reliability and longevity of microelectronic devices.

Applications Across Industries

The application of laser welding machines in the manufacturing of microelectronic devices spans across various industries. In the medical field, they are instrumental in producing implantable medical devices with precise dimensions and biocompatibility. In the telecommunications sector, laser-welded components enable the development of compact and high-performance communication devices. Moreover, in the automotive and aerospace industries, these machines contribute to the production of miniaturized sensors and control systems that enhance safety and efficiency.

Future Prospects

As technology continues to advance, the role of laser welding machines in the manufacturing of microelectronic devices is expected to expand further. Ongoing research and development efforts aim to enhance the capabilities of these machines, enabling even finer precision and greater efficiency. With each innovation, the boundaries of what is achievable in the realm of microelectronics are pushed, paving the way for the creation of increasingly sophisticated and compact electronic devices that drive progress in various fields.

In conclusion, laser welding machines have revolutionized the manufacturing of microelectronic devices by offering precision, reliability, and durability previously unattainable with traditional methods. As they continue to break boundaries and push the limits of technology, their role in shaping the future of microelectronics remains indispensable.