As various industries attach more importance to creative design and brand expression, the application scenarios of large-scale content engraving are becoming more and more extensive. Whether it is the art theme wall in the shopping mall or the carved decoration of the city landmark, the demand for large-scale engraving content is driving technological innovation. However, traditional engraving methods are difficult to meet these requirements. Manual engraving is highly dependent on the skills of craftsmen, with low efficiency and high error rate, while traditional mechanical engraving equipment often has problems when processing complex graphics, especially material limitations and insufficient detail expression. Laser engraving machines have broken through the bottleneck of traditional engraving technology with non-contact processing, extremely high detail fidelity and adaptability to large-area work, becoming an ideal choice for the market.

Laser source type: basic technology for large-scale engraving

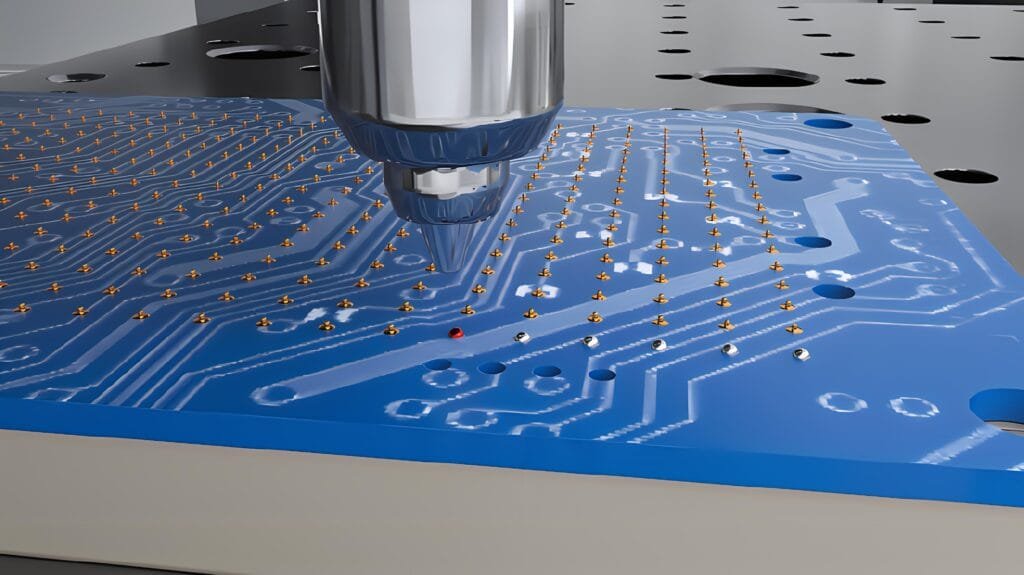

Laser light source is one of the core technologies of laser engraving machines. Different types of light sources directly determine the scope of application and engraving effect of the equipment. In large-scale content engraving, CO2 lasers are often used for processing non-metallic materials, such as wood, acrylic and cloth, because of their high absorption rate of these materials, fast engraving efficiency and fine effect. Fiber lasers are famous for their high energy density and excellent metal processing capabilities. They are particularly suitable for engraving hard materials such as metal sheets, aluminum alloys and stainless steel, and they perform well in large-area metal pattern engraving. The ultraviolet laser, with its ultra-short wavelength cold processing characteristics, can accurately process heat-sensitive materials such as glass and plastic, and plays a key role in large-scale pattern design that requires extremely high precision. Selecting a suitable light source according to the engraving material and design requirements is the first step to achieve high-quality large-scale content engraving.

Large-format worktable: Stability is the basis for large-scale engraving

In large-scale content engraving, the design and stability of the workbench directly affect the engraving effect and operating efficiency. The larger the size of the large-format workbench, the more it can meet the needs of large-scale engraving tasks such as billboards and wall decorations. However, this kind of workbench not only needs to be of sufficient size, but also must have extremely high stability. Especially when engraving continuously for a long time, an unstable workbench may cause pattern misalignment or uneven engraving. Some high-end laser engraving machines are equipped with a steel structure base and anti-vibration design to ensure the stability of the workbench. In addition, adjustable clamps and magnetic fixtures can further enhance the fixing effect of the material, whether it is thin sheet materials or heavy plates, it can maintain accurate engraving. Choosing a stable and reliable large-format workbench is the basic guarantee for large-scale content engraving.

Layering and Partitioning: Design Strategies for Large-Scale Content Sculpting

In large-scale content engraving, the refinement of design strategies is crucial. Layering is a common method, which layers complex graphics according to depth, color or material properties to ensure that each layer can be engraved independently and does not interfere with each other. This method not only improves engraving efficiency, but also achieves a richer three-dimensional effect. Partition engraving is suitable for ultra-large-format designs, especially in billboards or architectural decorations, where the overall pattern is divided into multiple areas and engraved one by one. In order to ensure seamless connection between areas, it is necessary to reserve splicing positions on the edges of the graphics during design, and combine the positioning system of the laser engraving machine to accurately adjust the position. Through these design techniques, users can greatly improve the efficiency and operability of large-scale content engraving while ensuring quality.

From testing to mass production: a complete guide to achieving large-scale content engraving

In the actual operation of large-scale content engraving, following a scientific process is the key to completing the task efficiently. First of all, before formal engraving, it is necessary to determine the best parameters through sample testing. This step includes selecting the appropriate laser power, engraving speed, and focal distance. Different materials react differently to lasers. For example, metals require higher power, while wood requires heat control to prevent burning. During the testing phase, the correspondence between each parameter and the engraving effect is recorded to provide a reference for subsequent operations.

After entering the mass production phase, the stability of the equipment is particularly important. In large-scale engraving, long-term operation may cause the equipment temperature to rise or the laser to attenuate, so it is necessary to monitor the equipment status regularly to ensure parameter consistency. In order to avoid repeated parameter settings, the parameter storage function of the engraving machine can be used to quickly call the best settings recorded in the test. In addition, in order to improve efficiency, a partition processing strategy can be adopted to complete the engraving content piece by piece, and then splice the overall pattern. Through this process design, every step of large-scale content engraving is in order, thereby achieving higher quality and output efficiency.

Large-scale engraving in architectural decoration: complex patterns are easily achieved

The dual requirements of artistry and scale in the architectural decoration industry make large-scale content engraving an indispensable technical support. For example, a construction company once produced an entire 30-square-meter hollow decorative wall for a hotel. This decorative wall is themed with natural scenery, and the pattern includes complicated leaves, mountains and water ripples, which are difficult to complete efficiently with traditional carving techniques.

Using a laser engraving machine, the designer layers the overall pattern to accurately present everything from the delicate leaf veins to the large-area background. In production, the equipment’s high-power laser ensures precise cutting of materials, while the autofocus function avoids fluctuations in engraving depth. In the end, the carved decorative wall is not only beautiful and elegant, but also achieves perfect docking of patterns during installation, without the need for subsequent adjustments. This case proves that laser engraving technology can transform complex requirements for architectural decoration into high-quality actual works, while significantly saving time and costs.

Intelligent and green development prospects of large-scale content engraving

The future of laser engraving technology will usher in unprecedented intelligent and green development. First, innovation in efficient lasers will be a key factor in driving the development of large-scale content engraving. With the improvement of laser performance, especially breakthroughs in power and beam quality, large-scale engraving can not only be completed faster, but the engraving accuracy has also been significantly improved. The beam control and thermal energy management of the new generation laser enable it to maintain stable and efficient performance when performing large-scale content engraving. The technological advancement of lasers will directly promote the widespread application of large-scale content engraving in advertising, architecture and artistic creation.

The introduction of AI will enable laser engraving machines to have stronger intelligent functions. Through automated control of artificial intelligence, laser engraving machines will be able to automatically adjust laser parameters according to different material types, engraving patterns and size requirements to ensure engraving quality and consistency. AI can also automatically generate content and generate patterns that meet engraving standards based on creativity and design requirements. Intelligent design and control make large-scale content engraving no longer dependent on manual intervention, thereby improving production efficiency and engraving accuracy, and solving many bottlenecks of traditional engraving methods.

In terms of environmental protection, the gradual advancement of green engraving technology will make laser engraving more energy-saving and environmentally friendly. Future laser engraving equipment will focus on improving energy utilization, reducing waste and energy waste, and meeting the requirements of global sustainable development. Laser engraving machines have natural advantages in material utilization, which can reduce unnecessary waste and reduce environmental pollution. Through energy-saving technology and environmentally friendly design, large-scale content engraving can not only improve production efficiency, but also effectively promote the development of the manufacturing industry in a greener and low-carbon direction.