Laser engraver machine have become indispensable in modern industrial production. From electronic components and medical devices to automotive parts and consumer packaging, laser marking machines offer efficient, precise, and durable marking solutions. However, with a myriad of brands and models available on the market, selecting the right laser marking machine can be a daunting task. This article will guide you through key factors to consider to help you make an informed choice.

1. Marking Material

The type of material you need to mark is a crucial factor in choosing a laser marking machine. Different types of lasers work best with different materials:

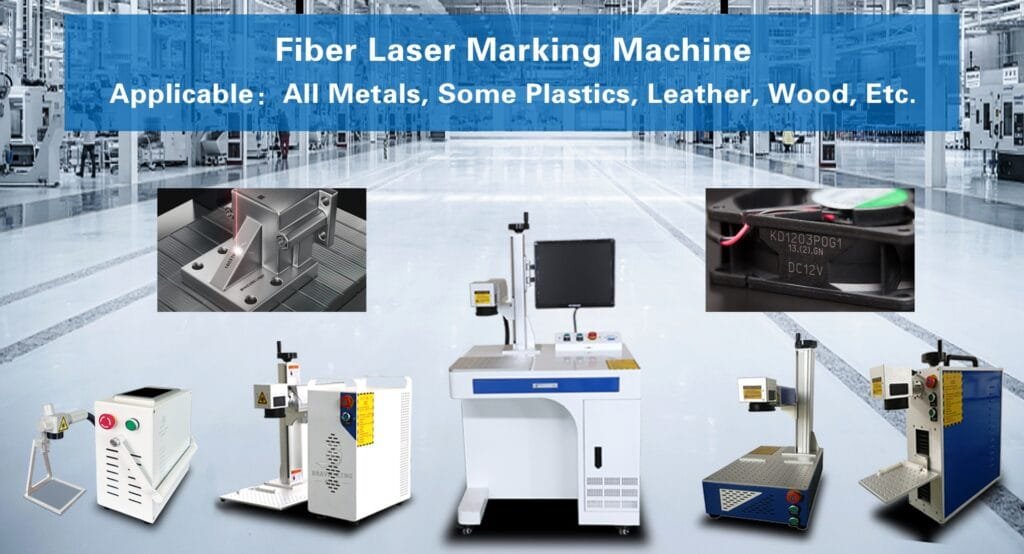

- Fiber Laser Engraver Machine: Ideal for marking metals like aluminum, copper, stainless steel, and some plastics. They have high electro-optical conversion efficiency and long service life, making them a top choice for the metal processing industry.

- CO2 Laser Engraver Machine: Primarily used for non-metal materials such as wood, paper, leather, glass, and acrylic. These are commonly used in packaging, apparel, and handicrafts.

- UV Laser Engraver Machine: Due to their short wavelength, these are suitable for high-precision marking on materials like electronic components, semiconductor chips, and polymers. UV lasers provide fine and clear marks with minimal thermal impact on the material.

Identifying the primary materials you need to process will significantly narrow down your options.

2. Marking Requirements

Your specific marking needs are another critical factor. Consider the following aspects:

- Marking Precision: If your products require high-precision marking, such as electronic components or medical devices, a high-precision laser marking machine is essential.

- Marking Speed: If your production line requires high-speed marking to enhance efficiency, look for a high-speed laser marking machine. Fiber lasers generally offer faster marking speeds.

- Marking Area: The marking area refers to the maximum working area the laser can cover. For larger products or extensive marking areas, choose a machine with a larger marking area.

3. Equipment Cost

Cost is a significant consideration for any purchaser. Laser marking machine prices vary based on technology, power, and brand. Generally, fiber laser marking machines are more expensive but offer longer lifespans and lower maintenance costs, making them cost-effective over time. CO2 laser marking machines are moderately priced, while UV laser marking machines tend to be more expensive due to their complex technology.

When considering equipment costs, look beyond the initial purchase price to include long-term usage and maintenance costs. For instance, fiber lasers have long-lasting lasers that typically do not need replacement, whereas CO2 lasers might require periodic laser tube replacement.

4. Brand and After-Sales Service

The brand and after-sales service are also crucial when selecting a laser marking machine. Reputable brands usually offer more mature technology and better product quality. Moreover, a robust after-sales service team can provide timely technical support and maintenance, ensuring the smooth operation of your production line.

When choosing a brand, consider market reputation and user reviews to understand the actual performance and service quality. Opt for brands with local service teams to ensure quick service response when needed.

5. Software Capabilities

The control software of the Laser Engraver Machine directly impacts its ease of use and marking quality. A powerful and user-friendly software system can significantly enhance work efficiency and marking quality.

Ensure the software supports various file formats, offers multiple marking modes (such as vector marking and bitmap marking), and allows for easy parameter adjustment and program creation. Advanced features like auto-focusing, image recognition, and QR code generation can further improve precision and efficiency.

6. Environmental Adaptability

Consider the environmental adaptability of the laser marking machine. Different production environments have different requirements. For instance, if working in high-temperature, high-humidity, or corrosive gas environments, choose a laser marking machine with good sealing and environmental resistance. Additionally, if your production line requires mobility or frequent repositioning, a portable or compact laser marking machine would be more suitable.

7. Energy Consumption and Environmental Impact

With rising environmental awareness and energy costs, the energy consumption and environmental performance of laser marking machines have become important factors. Fiber laser marking machines, known for their high electro-optical conversion rate, consume less energy, making them ideal for energy-efficient and environmentally friendly operations. Lower energy consumption also translates to reduced long-term operational costs.

Environmental performance includes whether the laser marking machine produces harmful gases or waste during operation. High-end laser marking machines often feature effective exhaust systems to minimize environmental pollution.

Conclusion

Choosing the right Laser Engraver Machine requires a comprehensive consideration of marking materials, marking requirements, equipment costs, brand and after-sales service, software capabilities, environmental adaptability, and energy consumption. By analyzing and balancing these factors, you can find the laser marking machine that best suits your production needs, ensuring efficient and stable operation.

We hope this analysis provides valuable guidance in your selection process and helps you make an informed decision.