Laser Engraving: Understanding the Process

Laser engraving is a precision technique that involves transforming materials into vapor, creating deep, permanent marks. Think of the laser beam as a refined chisel, intricately etching marks by selectively removing layers from the material’s surface. The laser targets specific areas with concentrated energy, generating the intense heat needed for vaporization.

In this comprehensive article, we delve into the intricacies of how laser engraving functions and how to go about selecting an appropriate laser engraving machine.

Before we dive into the details, take a moment to watch a brief video showcasing the laser engraving process using a fiber laser. This video highlights the exceptional quality of contrasts, marking speed, and the emission of fumes during laser engraving.

Choosing Between Laser Engraving and Laser Etching Selecting the right laser marking process hinges on three critical factors:

- Marking Durability: The ability to maintain legibility under harsh conditions.

- Marking Speed: The time it takes to mark, preventing production bottlenecks.

- Material Compatibility: Ensuring the marking method suits the material.

Laser engraving technology is typically employed for engraving metal workpieces that will endure various types of wear and surface treatments. It excels with steel and aluminum, including anodized and die-cast aluminum.

One standout feature of this method is its capability to engrave 2D codes that maintain high legibility even after undergoing post-processing treatments. These treatments may involve shot blasting, e-coating, and heat treatments, effectively addressing complex traceability requirements.

However, when extreme durability is not the primary concern, laser etching is often the preferred choice due to its high-speed nature and reduced reliance on material ablation.

Laser etching accommodates a wider range of materials, including steel, aluminum, anodized aluminum, lead, magnesium, and zinc. Additionally, there’s a specialized technique called laser annealing that can be used to mark metals such as stainless steel.

From Solid to Gas: The Sublimation Process While laser etching involves melting the material’s surface to modify its texture, laser marking achieves sublimation, transforming the material surface directly from solid to gas without passing through a liquid phase.

To achieve sublimation, the laser engraving system must generate an abundance of energy to rapidly elevate the material’s surface to its vaporization temperature within milliseconds. Given the extreme temperatures required for sublimation, laser marking systems are notably potent tools.

When the material reaches this temperature, it vaporizes into fumes. Consequently, when purchasing a laser system, it should invariably come equipped with a fume extraction system to safeguard the working environment, along with an air knife to protect the laser’s lens.

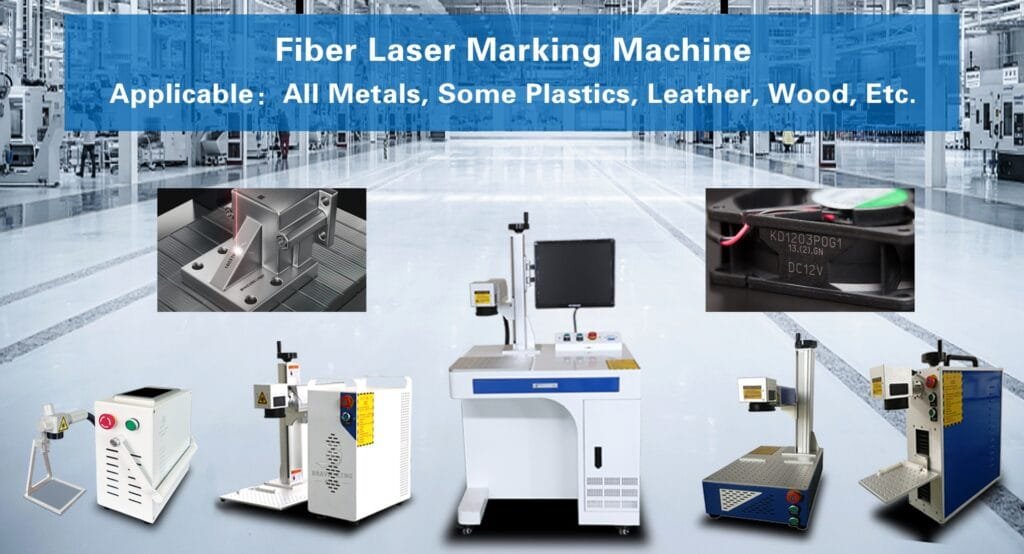

Fiber lasers are especially well-suited for engraving tasks due to their capacity to generate a wavelength that interacts effectively with metals.